Page 72 - Environmental Control in Petroleum Engineering

P. 72

60 Environmental Control in Petroleum Engineering

99% of the hydrocarbon vapors and 95% of the sulfur in the casing

gas. Because of the sales value of the condensed hydrocarbon vapors,

these systems can pay out within a few years,

2.3.3 Fugitive Emissions

Another source of air pollutants are the fugitive emissions of

volatile hydrocarbons. These are hydrocarbons that escape from pro-

duction systems through leaking components like valves, flanges,

pumps, compressors, connections, hatches, sight glasses, dump level

arms, packing seals, fittings, and instrumentation. Valves are usually

the most common components that leak. These emissions generally

result from the improper fit, wear and tear, and corrosion of equipment.

Although the leak rate from individual components is normally small,

the cumulative emissions from an oil field containing a large number

of components can be significant.

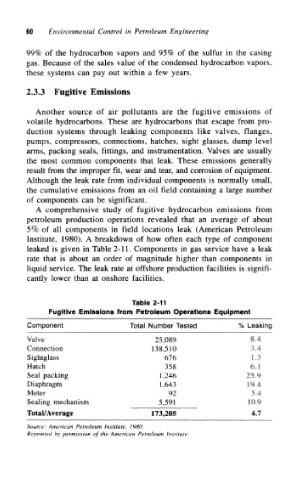

A comprehensive study of fugitive hydrocarbon emissions from

petroleum production operations revealed that an average of about

5% of all components in field locations leak (American Petroleum

Institute, 1980). A breakdown of how often each type of component

leaked is given in Table 2-11. Components in gas service have a leak

rate that is about an order of magnitude higher than components in

liquid service. The leak rate at offshore production facilities is signifi–

cantly lower than at onshore facilities,

Table 2-11

Fugitive Emissions from Petroleum Operations Equipment

Component Total Number Tested % Leaking

Valve 25,089 8.4

Connection 138,510 3.4

Sightglass 676 1.3

Hatch 358 6,1

Seal packing 1,246 25.9

Diaphragm 1,643 19.4

Meter 92 5,4

Sealing mechanism 5,591 10.9

Total/Average 173,205 4.7

Source: American Petroleum Institute, 1980.

Reprinted by permission of the American Petroleum Institute,