Page 53 - Facility Piping Systems Handbook for Industrial, Commercial, and Healthcare Facilities

P. 53

PIPING

PIPING 2.3

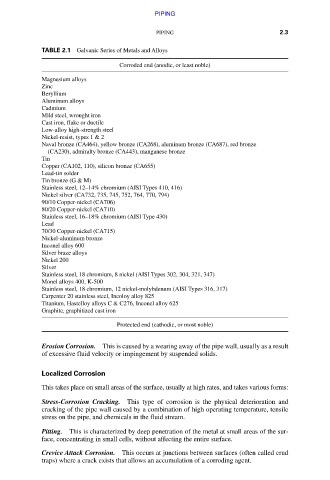

TABLE 2.1 Galvanic Series of Metals and Alloys

Corroded end (anodic, or least noble)

Magnesium alloys

Zinc

Beryllium

Aluminum alloys

Cadmium

Mild steel, wrought iron

Cast iron, flake or ductile

Low-alloy high-strength steel

Nickel-resist, types 1 & 2

Naval bronze (CA464), yellow bronze (CA268), aluminum bronze (CA687), red bronze

(CA230), admiralty bronze (CA443), manganese bronze

Tin

Copper (CA102, 110), silicon bronze (CA655)

Lead-tin solder

Tin bronze (G & M)

Stainless steel, 12–14% chromium (AISI Types 410, 416)

Nickel silver (CA732, 735, 745, 752, 764, 770, 794)

90/10 Copper-nickel (CA706)

80/20 Copper-nickel (CA710)

Stainless steel, 16–18% chromium (AISI Type 430)

Lead

70/30 Copper-nickel (CA715)

Nickel-aluminum bronze

Inconel alloy 600

Silver braze alloys

Nickel 200

Silver

Stainless steel, 18 chromium, 8 nickel (AISI Types 302, 304, 321, 347)

Monel alloys 400, K-500

Stainless steel, 18 chromium, 12 nickel-molybdenum (AISI Types 316, 317)

Carpenter 20 stainless steel, Incoloy alloy 825

Titanium, Hastelloy alloys C & C276, Inconel alloy 625

Graphite, graphitized cast iron

Protected end (cathodic, or most noble)

Erosion Corrosion. This is caused by a wearing away of the pipe wall, usually as a result

of excessive fluid velocity or impingement by suspended solids.

Localized Corrosion

This takes place on small areas of the surface, usually at high rates, and takes various forms:

Stress-Corrosion Cracking. This type of corrosion is the physical deterioration and

cracking of the pipe wall caused by a combination of high operating temperature, tensile

stress on the pipe, and chemicals in the fluid stream.

Pitting. This is characterized by deep penetration of the metal at small areas of the sur-

face, concentrating in small cells, without affecting the entire surface.

Crevice Attack Corrosion. This occurs at junctions between surfaces (often called crud

traps) where a crack exists that allows an accumulation of a corroding agent.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.accessengineeringlibrary.com)

Copyright © 2009 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.