Page 92 - Failure Analysis Case Studies II

P. 92

77

. . . -

.

. .

A

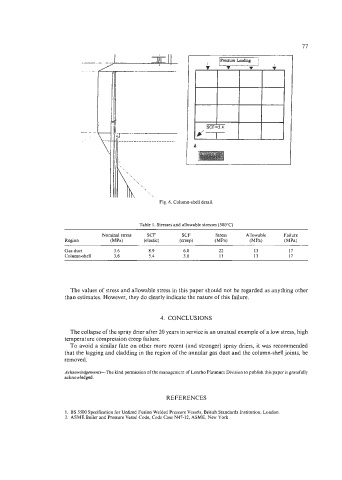

Fig. 6. Column-shell detail.

Table 1. Stresses and allowable stresses (SOO'C)

Nominal stress SCF SCF Stress Allowable Failure

Region (MPa) (elastic) (creep) (MPa) (MPa) @Pa)

Gas duct 3.6 8.9 6.0 22 13 17

Column-shell 3.6 5.4 3.0 11 13 17

The values of stress and allowable stress in this paper should not be regarded as anything other

than estimates. However, they do clearly indicate the nature of this failure.

4. CONCLUSIONS

The collapse of the spray drier after 20 years in service is an unusual example of a low stress, high

temperature compression creep failure.

To avoid a similar fate on other more recent (and stronger) spray driers, it was recommended

that the lagging and cladding in the region of the annular gas duct and the column-shell joints, be

removed.

Acknowledgements-The kind permission of the management of Lonrho Platinum Division to publish this paper is gratefully

acknowledged.

REFERENCES

1. BS 5500 Specification for Unfired Fusion Welded Pressure Vessels, British Standards Institution, London.

2. ASME Boiler and Pressure Vessel Code, Code Case N47-12, ASME, New York.