Page 331 - Fair, Geyer, and Okun's Water and wastewater engineering : water supply and wastewater removal

P. 331

JWCL344_ch08_265-296.qxd 8/2/10 9:53 PM Page 291

Problems/Questions 291

Reclaimed water tank

Residential

Commercial Potable

and industrial water

tank

Lakes, rivers,

and wells

Water treatment plant

Water reclamation plant

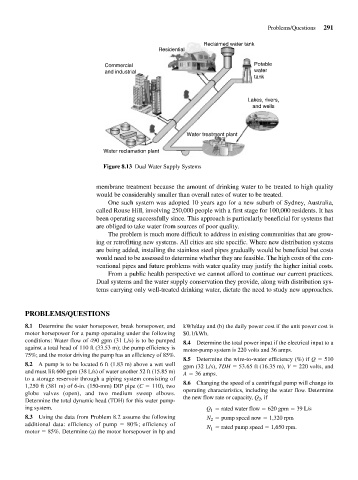

Figure 8.13 Dual Water Supply Systems

membrane treatment because the amount of drinking water to be treated to high quality

would be considerably smaller than overall rates of water to be treated.

One such system was adopted 10 years ago for a new suburb of Sydney, Australia,

called Rouse Hill, involving 250,000 people with a first stage for 100,000 residents. It has

been operating successfully since. This approach is particularly beneficial for systems that

are obliged to take water from sources of poor quality.

The problem is much more difficult to address in existing communities that are grow-

ing or retrofitting new systems. All cities are site specific. Where new distribution systems

are being added, installing the stainless steel pipes gradually would be beneficial but costs

would need to be assessed to determine whether they are feasible. The high costs of the con-

ventional pipes and future problems with water quality may justify the higher initial costs.

From a public health perspective we cannot afford to continue our current practices.

Dual systems and the water supply conservation they provide, along with distribution sys-

tems carrying only well-treated drinking water, dictate the need to study new approaches.

PROBLEMS/QUESTIONS

8.1 Determine the water horsepower, break horsepower, and kWh/day and (b) the daily power cost if the unit power cost is

motor horsepower for a pump operating under the following $0.1/kWh.

conditions: Water flow of 490 gpm (31 L/s) is to be pumped

8.4 Determine the total power input if the electrical input to a

against a total head of 110 ft (33.53 m); the pump efficiency is

motor-pump system is 220 volts and 36 amps.

75%; and the motor driving the pump has an efficiency of 85%.

8.5 Determine the wire-to-water efficiency (%) if Q 510

8.2 A pump is to be located 6 ft (1.83 m) above a wet well

gpm (32 L/s), TDH 53.65 ft (16.35 m), V 220 volts, and

and must lift 600 gpm (38 L/s) of water another 52 ft (15.85 m)

A 36 amps.

to a storage reservoir through a piping system consisting of

8.6 Changing the speed of a centrifugal pump will change its

1,250 ft (381 m) of 6-in. (150-mm) DIP pipe (C 110), two

operating characteristics, including the water flow. Determine

globe valves (open), and two medium sweep elbows.

the new flow rate or capacity, Q 2 , if

Determine the total dynamic head (TDH) for this water pump-

ing system. Q 1 rated water flow 620 gpm 39 L/s

8.3 Using the data from Problem 8.2 assume the following N 2 pump speed now 1,320 rpm

additional data: efficiency of pump 80%; efficiency of

N 1 rated pump speed 1,650 rpm.

motor 85%. Determine (a) the motor horsepower in hp and