Page 387 - Fair, Geyer, and Okun's Water and wastewater engineering : water supply and wastewater removal

P. 387

JWCL344_ch10_333-356.qxd 8/2/10 9:02 PM Page 347

10.7 Treatment and Disposal or Reuse of Wastewater 347

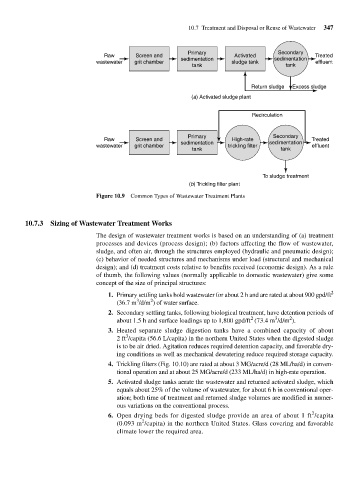

Primary Secondary

Raw Screen and Activated Treated

sedimentation sedimentation

wastewater grit chamber sludge tank effluent

tank tank

Return sludge Excess sludge

(a) Activated sludge plant

Recirculation

Primary Secondary

Raw Screen and High-rate Treated

sedimentation sedimentation

wastewater grit chamber trickling filter effluent

tank tank

To sludge treatment

(b) Trickling filter plant

Figure 10.9 Common Types of Wastewater Treatment Plants

10.7.3 Sizing of Wastewater Treatment Works

The design of wastewater treatment works is based on an understanding of (a) treatment

processes and devices (process design); (b) factors affecting the flow of wastewater,

sludge, and often air, through the structures employed (hydraulic and pneumatic design);

(c) behavior of needed structures and mechanisms under load (structural and mechanical

design); and (d) treatment costs relative to benefits received (economic design). As a rule

of thumb, the following values (normally applicable to domestic wastewater) give some

concept of the size of principal structures:

1. Primary settling tanks hold wastewater for about 2 h and are rated at about 900 gpd/ft 2

3

2

(36.7 m /d/m ) of water surface.

2. Secondary settling tanks, following biological treatment, have detention periods of

3

2

2

about 1.5 h and surface loadings up to 1,800 gpd/ft (73.4 m /d/m ).

3. Heated separate sludge digestion tanks have a combined capacity of about

3

2 ft /capita (56.6 L/capita) in the northern United States when the digested sludge

is to be air dried. Agitation reduces required detention capacity, and favorable dry-

ing conditions as well as mechanical dewatering reduce required storage capacity.

4. Trickling filters (Fig. 10.10) are rated at about 3 MG/acre/d (28 ML/ha/d) in conven-

tional operation and at about 25 MG/acre/d (233 ML/ha/d) in high-rate operation.

5. Activated sludge tanks aerate the wastewater and returned activated sludge, which

equals about 25% of the volume of wastewater, for about 6 h in conventional oper-

ation; both time of treatment and returned sludge volumes are modified in numer-

ous variations on the conventional process.

2

6. Open drying beds for digested sludge provide an area of about 1 ft /capita

2

(0.093 m /capita) in the northern United States. Glass covering and favorable

climate lower the required area.