Page 116 - Fiber Bragg Gratings

P. 116

3.1 Methods for fiber Bragg grating fabrication 95

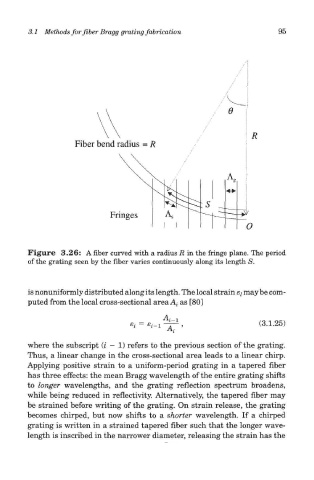

Figure 3.26: A fiber curved with a radius R in the fringe plane. The period

of the grating seen by the fiber varies continuously along its length S.

is nonuniformly distributed along its length. The local strain e z maybe com-

puted from the local cross-sectional area Aj as [80]

where the subscript (i — 1) refers to the previous section of the grating.

Thus, a linear change in the cross-sectional area leads to a linear chirp.

Applying positive strain to a uniform-period grating in a tapered fiber

has three effects: the mean Bragg wavelength of the entire grating shifts

to longer wavelengths, and the grating reflection spectrum broadens,

while being reduced in reflectivity. Alternatively, the tapered fiber may

be strained before writing of the grating. On strain release, the grating

becomes chirped, but now shifts to a shorter wavelength. If a chirped

grating is written in a strained tapered fiber such that the longer wave-

length is inscribed in the narrower diameter, releasing the strain has the