Page 178 - Fiber Fracture

P. 178

FRACTURE OF CARBON FIBERS 163

PAN-BASED CARBON FIBERS

Polyacrylonitrile (PAN) fibers are made by a variety of methods. The polymer is

made by free-radical polymerization either in solution or in a solvent-water suspension.

The polymer is then dried and re-dissolved in another solvent for spinning, either

by wet-spinning or dry-spinning. In the wet-spinning process the spin dope is forced

through a spinneret into a coagulating liquid and stretched, while in the dry-spinning

process the dope is spun into a hot gas chamber, and stretched. For high-strength carbon

fibers, it is important to avoid the formation of voids within the fiber at this step.

Dry-spun fibers are characterized by a 'dog-bone' cross-section, formed because the

perimeter of the fiber is quenched before much of the solvent is removed. The preferred

process for high-strength fiber today is wet-spinning. Processes for melt-spinning PAN

plasticized with water or polyethylene glycol have been developed, but are not practiced

commercially. A significant improvement in carbon fiber strength was obtained by

Moreton and Watt (1974) who spun the PAN precursor under clean room conditions.

The strength of fibers spun in this way and subsequently heat treated was found to

improve by >SO% over conventionally spun fibers. The mechanism is presumed to be

removal of small impurities which can act as crack initiators. This technology is believed

to be critical for production of high strength fibers such as Toray's T800 and T1000.

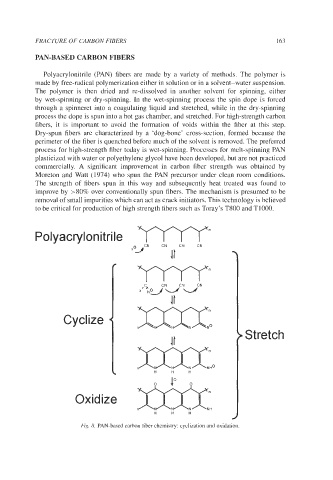

Polyacrylonitrile 7^r('(*

CN

Cyclize

Stretch

H H H

O P O

Oxidize

H H H

Fig. 8. PAN-based carbon fiber chemistry: cyclization and oxidation.