Page 351 - Fiber Fracture

P. 351

FRACTURE OF COMMON TEXTILE FIBRES 333

COTTON AND RELATED FIBRES

Structure and Stress-Strain Curves

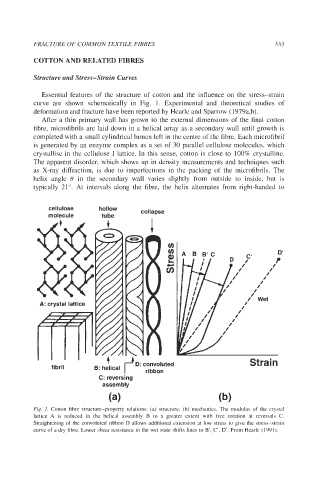

Essential features of the structure of cotton and the influence on the stress-strain

curve are shown schematically in Fig. 1. Experimental and theoretical studies of

deformation and fracture have been reported by Hearle and Sparrow (1979a,b).

After a thin primary wall has grown to the external dimensions of the final cotton

fibre, microfibrils are laid down in a helical array as a secondary wall until growth is

completed with a small cylindrical lumen left in the centre of the fibre. Each microfibril

is generated by an enzyme complex as a set of 30 parallel cellulose molecules, which

crystallise in the cellulose I lattice. In this sense, cotton is close to 100% crystalline.

The apparent disorder, which shows up in density measurements and techniques such

as X-ray diffraction, is due to imperfections in the packing of the microfibrils. The

helix angle 8 in the secondary wall varies slightly from outside to inside, but is

typically 21". At intervals along the fibre, the helix alternates from right-handed to

cellulose hollow collapse

molecule tube

C: reversing

assembly

Fig. 1. Cotton fibre structure-property relations: (a) structure; (b) mechanics. The modulus of the crystal

lattice A is reduced in the helical assembly B to a greater extent with free rotation at reversals C.

Straightening of the convoluted ribbon D allows additional extension at low stress to give the stress-strain

curve of a dry fibre. Lower shear resistance in the wet state shifts lines to B', C', D'. From Hearle (1991).