Page 91 - Fiber Fracture

P. 91

76 A.R. Bunsell

INTRODUCTION

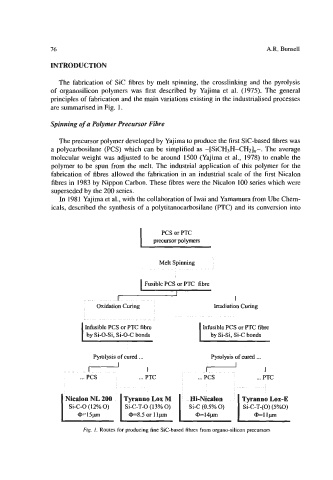

The fabrication of Sic fibres by melt spinning, the crosslinking and the pyrolysis

of organosilicon polymers was first described by Yajima et al. (1975). The general

principles of fabrication and the main variations existing in the industrialised processes

are summarised in Fig. I.

Spinning of a Polymer Precursor Fibre

The precursor polymer developed by Yajima to produce the first Sic-based fibres was

a polycarbosilane (PCS) which can be simplified as -[SiCH3H-CH2In-. The average

molecular weight was adjusted to be around 1500 (Yajima et al., 1978) to enable the

polymer to be spun from the melt. The industrial application of this polymer for the

fabrication of fibres allowed the fabrication in an industrial scale of the first Nicalon

fibres in 1983 by Nippon Carbon. These fibres were the Nicalon 100 series which were

superseded by the 200 series.

In 1981 Yajima et al., with the collaboration of Iwai and Yamamura from Ube Chem-

icals, described the synthesis of a polytitanocarbosilane (PTC) and its conversion into

PCS or PTC

Melt Spinning

Fusible PCS or PX fibre

r I I

Oxidation Curing Irradiation Curing

Jnkible PCS or PTC fibre I Infusible PCS or PTC fibre

I by Si-0-Si, Si-0-C bonds by Si-Si, Si-C bonds

+ +

Pyrolysis of cured ...

Pyrolysis of cured ...

I

I

... PCS ... PTC ... PCS ... FTC

1 Nhlon NL 200 Tyranno Lox M Si-C (0.5% 0) Tyranno Lox-E

@=15pm I e8.5 or 1 lp I

Hi-Nica4an

Sic-0 (12% 0)

Sic-T-O (13% 0)

Si-C-T-(O) (5%0)

@=14pm I @=llpm

Fig. I. Routes for producing fine Sic-based fibres from organo-silicon precursors