Page 412 - Flexible Robotics in Medicine

P. 412

406 Chapter 18

Table 18.1: Selected materials for components.

Component Material Reason

Forceps Stainless steel (316L) Biocompatible, rigid, and resistant to wear

Connector beads Stainless steel (316L) Biocompatible and rigid

Spring Stainless steel (316L) Biocompatible and rigid

Gooseneck Stainless steel (316L) Biocompatible, able to withstand tension during withdrawal

Cables Nylon (316L) Small diameter, able to be threaded through connector

beads, able to transmit forces

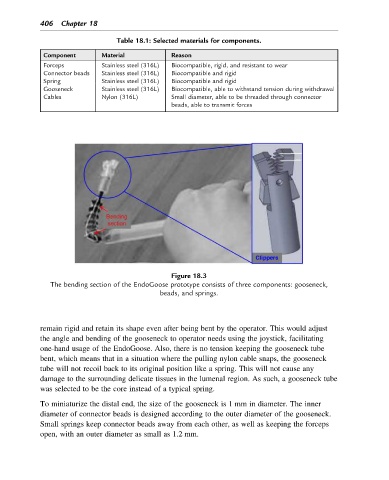

Figure 18.3

The bending section of the EndoGoose prototype consists of three components: gooseneck,

beads, and springs.

remain rigid and retain its shape even after being bent by the operator. This would adjust

the angle and bending of the gooseneck to operator needs using the joystick, facilitating

one-hand usage of the EndoGoose. Also, there is no tension keeping the gooseneck tube

bent, which means that in a situation where the pulling nylon cable snaps, the gooseneck

tube will not recoil back to its original position like a spring. This will not cause any

damage to the surrounding delicate tissues in the lumenal region. As such, a gooseneck tube

was selected to be the core instead of a typical spring.

To miniaturize the distal end, the size of the gooseneck is 1 mm in diameter. The inner

diameter of connector beads is designed according to the outer diameter of the gooseneck.

Small springs keep connector beads away from each other, as well as keeping the forceps

open, with an outer diameter as small as 1.2 mm.