Page 17 - Fluid Catalytic Cracking Handbook

P. 17

Fluid Catalytic Cracking Handbook

Products

Regen

Flue

Gas

Transfer

Line

Reactor

Air Blower

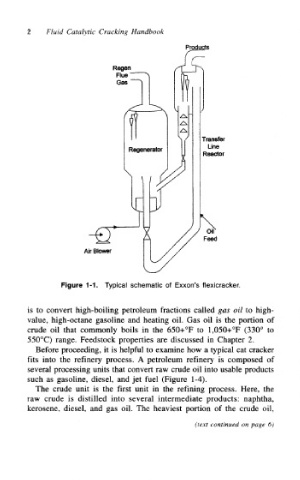

Figure 1-1. Typical schematic of Exxon's flexicracker,

is to convert high-boiling petroleum fractions called gas oil to high-

value, high-octane gasoline and heating oil. Gas oil is the portion of

crude oil that commonly boils in the 650+°F to 1,050+°F (330° to

550°C) range. Feedstock properties are discussed in Chapter 2.

Before proceeding, it is helpful to examine how a typical cat cracker

fits into the refinery process. A petroleum refinery is composed of

several processing units that convert raw crude oil into usable products

such as gasoline, diesel, and jet fuel (Figure 1-4).

The crude unit is the first unit in the refining process. Here, the

raw crude is distilled into several intermediate products: naphtha,

kerosene, diesel, and gas oil. The heaviest portion of the crude oil,

(text continued on page 6)