Page 19 - Fluid Catalytic Cracking Handbook

P. 19

Fluid Catalytic Cracking Handbook

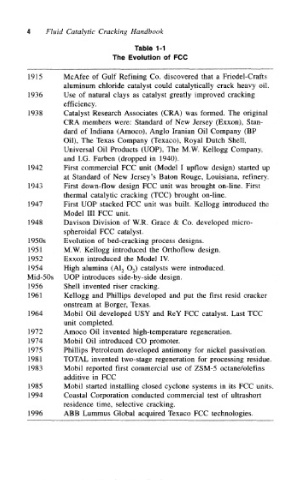

Table 1-1

The Evolution of FCC

1915 McAfee of Gulf Refining Co. discovered that a Friedel-Crafts

aluminum chloride catalyst could catalytically crack heavy oil.

1936 Use of natural clays as catalyst greatly improved cracking

efficiency.

1938 Catalyst Research Associates (CRA) was formed. The original

CRA members were: Standard of New Jersey (Exxon), Stan-

dard of Indiana (Amoco), Anglo Iranian Oil Company (BP

Oil), The Texas Company (Texaco), Royal Dutch Shell,

Universal Oil Products (UOP), The M.W, Kellogg Company,

and I.G. Farben (dropped in 1940).

1942 First commercial FCC unit (Model I upflow design) started up

at Standard of New Jersey's Baton Rouge, Louisiana, refinery.

1943 First down-flow design FCC unit was brought on-line. First

thermal catalytic cracking (TCC) brought on-line.

1947 First UOP stacked FCC unit was built. Kellogg introduced the

Model III FCC unit.

1948 Davison Division of W.R. Grace & Co. developed micro-

spheroidal FCC catalyst.

1950s Evolution of bed-cracking process designs.

1951 M.W. Kellogg introduced the Orthoflow design.

1952 Exxon introduced the Model IV.

1954 High alumina (A1 2 O 2) catalysts were introduced.

Mid-50s UOP introduces side-by-side design.

1956 Shell invented riser cracking.

1961 Kellogg and Phillips developed and put the first resid cracker

onstream at Borger, Texas.

1964 Mobil Oil developed USY and ReY FCC catalyst. Last TCC

unit completed.

1972 Amoco Oil invented high-temperature regeneration.

1974 Mobil Oil introduced CO promoter.

1975 Phillips Petroleum developed antimony for nickel passivation.

1981 TOTAL invented two-stage regeneration for processing residue,

1983 Mobil reported first commercial use of ZSM-5 octane/olefins

additive in FCC

1985 Mobil started installing closed cyclone systems in its FCC units.

1994 Coastal Corporation conducted commercial test of ultrashort

residence time, selective cracking.

1996 ABB Lummus Global acquired Texaco FCC technologies.