Page 23 - Fluid Catalytic Cracking Handbook

P. 23

Process Description

Vent to Main Column

-cSi—^

Slurry

I

Feed Preheater

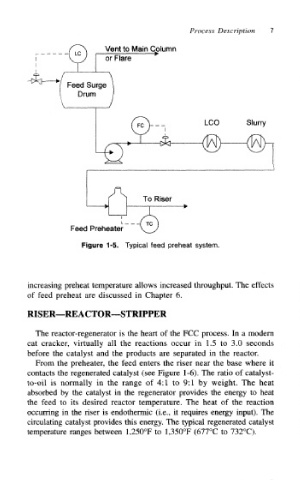

Figure 1-5. Typical feed preheat system.

increasing preheat temperature allows increased throughput. The effects

of feed preheat are discussed in Chapter 6.

RISER—REACTOR—STRIPPER

The reactor-regenerator is the heart of the FCC process. In a modern

cat cracker, virtually all the reactions occur in 1.5 to 3.0 seconds

before the catalyst and the products are separated in the reactor.

From the preheater, the feed enters the riser near the base where it

contacts the regenerated catalyst (see Figure 1-6). The ratio of catalyst-

to-oil is normally in the range of 4:1 to 9:1 by weight. The heat

absorbed by the catalyst in the regenerator provides the energy to heat

the feed to its desired reactor temperature. The heat of the reaction

occurring in the riser is endothermic (i.e., it requires energy input). The

circulating catalyst provides this energy. The typical regenerated catalyst

temperature ranges between 1,250°F to 1,350°F (677°C to 732°C).