Page 28 - Fluid Catalytic Cracking Handbook

P. 28

12 Fluid Catalytic Cracking Handbook

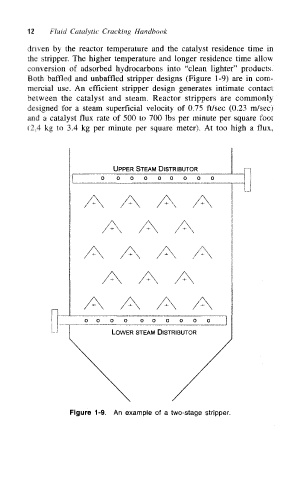

driven by the reactor temperature and the catalyst residence time in

the stripper. The higher temperature and longer residence time allow

conversion of adsorbed hydrocarbons into "clean lighter" products.

Both baffled and unbaffled stripper designs (Figure 1-9) are in com-

mercial use. An efficient stripper design generates intimate contact

between the catalyst and steam. Reactor strippers are commonly

designed for a steam superficial velocity of 0.75 ft/sec (0.23 m/sec)

and a catalyst flux rate of 500 to 700 lbs per minute per square foot

(2.4 kg to 3.4 kg per minute per square meter). At too high a flux,

UPPER STEAM DISTRIBUTOR

LOWER STEAM DISTRIBUTOR

Figure 1-9. An example of a two-stage stripper.