Page 27 - Fluid Catalytic Cracking Handbook

P. 27

Process Description 11

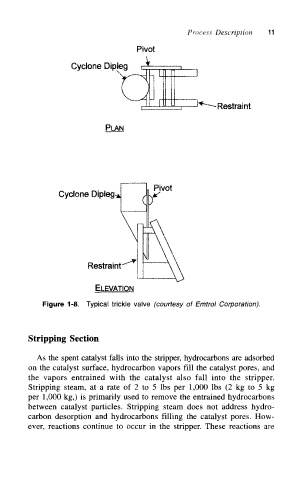

Pivot

Cyclone Dipleg

Restraint

PLAN

Pivot

Cyclone Dipleg*

Restraint

ELEVATION

Figure 1-8. Typical trickle valve (courtesy of Emtrol Corporation),

Stripping Section

As the spent catalyst falls into the stripper, hydrocarbons are adsorbed

on the catalyst surface, hydrocarbon vapors fill the catalyst pores, and

the vapors entrained with the catalyst also fall into the stripper.

Stripping steam, at a rate of 2 to 5 Ibs per 1,000 lbs (2 kg to 5 kg

per 1,000 kg,) is primarily used to remove the entrained hydrocarbons

between catalyst particles. Stripping steam does not address hydro-

carbon desorption and hydrocarbons filling the catalyst pores. How-

ever, reactions continue to occur in the stripper. These reactions are