Page 78 - Fluid Catalytic Cracking Handbook

P. 78

56 Fluid Catalytic Cracking Handbook

few others, feeds with high nitrogen also have other impurities.

Therefore, it is difficult to evaluate deleterious effects of nitrogen

alone. Hydrotreating the feed reduces not only the nitrogen content

but also most other contaminants.

Aside from catalyst poisoning, nitrogen is detrimental to the unit

operation in several other areas. In the riser, some of the nitrogen is

converted to ammonia and cyanide (H-CN). Cyanide accelerates the

corrosion rate of the FCC gas plant equipment; it removes the protec-

tive sulfide scale and exposes bare metal to further corrosion. This

corrosion generates atomic hydrogen that ultimately results in hydrogen

blistering. Cyanide formation tends to increase with cracking severity.

In addition, some of the nitrogen compounds end up in light cycle

oil (LCO) as pyrolles and pyridines [5]. These compounds are easily

oxidized and will affect color stability. The amount of nitrogen in the

LCO depends on the conversion. An increase in conversion decreases

the percentage of nitrogen in the LCO and increases the percentage

on the catalyst.

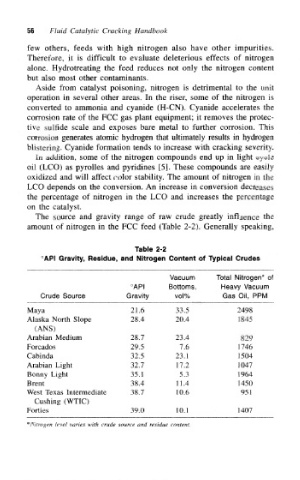

The source and gravity range of raw crude greatly influence the

amount of nitrogen in the FCC feed (Table 2-2). Generally speaking,

Table 2-2

API Gravity, Residue, and Nitrogen Content of Typical Crudes

Vacuum Total Nitrogen* of

°API Bottoms, Heavy Vacuum

Crude Source Gravity vol% Gas Oil, PPM

Maya 21.6 33.5 2498

Alaska North Slope 28.4 20.4 1845

(ANS)

Arabian Medium 28.7 23.4 829

Forcados 29.5 7.6 1746

Cabinda 32.5 23.1 1504

Arabian Light 32.7 17.2 1047

Bonny Light 35.1 5.3 1964

Brent 38.4 11.4 1450

West Texas Intermediate 38.7 10.6 951

Gushing (WTIC)

Forties 39.0 10.1 1407

*Nitrogen level varies with crude source and residue content.