Page 171 - Fluid mechanics, heat transfer, and mass transfer

P. 171

EJECTORS 149

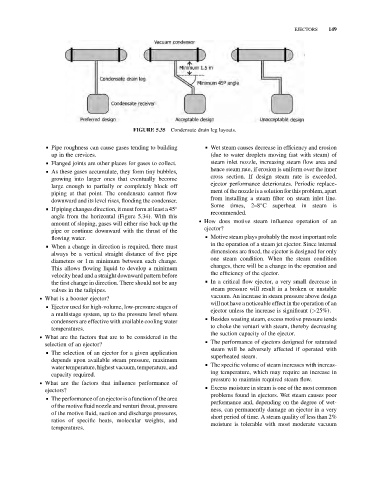

FIGURE 5.35 Condensate drain leg layouts.

& Pipe roughness can cause gases tending to building & Wet steam causes decrease in efficiency and erosion

up in the crevices. (due to water droplets moving fast with steam) of

& Flanged joints are other places for gases to collect. steam inlet nozzle, increasing steam flow area and

hence steam rate, if erosion is uniform over the inner

& As these gases accumulate, they form tiny bubbles,

cross section. If design steam rate is exceeded,

growing into larger ones that eventually become

large enough to partially or completely block off ejector performance deteriorates. Periodic replace-

ment of the nozzle is a solution for this problem, apart

piping at that point. The condensate cannot flow

from installing a steam filter on steam inlet line.

downward and its level rises, flooding the condenser.

Some times, 2–8 C superheat in steam is

& If piping changes direction, it must form at least a 45

recommended.

angle from the horizontal (Figure 5.34). With this

. How does motive steam influence operation of an

amount of sloping, gases will either rise back up the

ejector?

pipe or continue downward with the thrust of the

flowing water. & Motive steam plays probably the most important role

in the operation of a steam jet ejector. Since internal

& When a change in direction is required, there must

dimensions are fixed, the ejector is designed for only

always be a vertical straight distance of five pipe

one steam condition. When the steam condition

diameters or 1 m minimum between each change.

changes, there will be a change in the operation and

This allows flowing liquid to develop a minimum

the efficiency of the ejector.

velocity head and a straight downward pattern before

the first change in direction. There should not be any & In a critical flow ejector, a very small decrease in

valves in the tailpipes. steam pressure will result in a broken or unstable

vacuum. An increase in steam pressure above design

. What is a booster ejector?

will not have a noticeable effect in the operation of an

& Ejector used for high-volume, low-pressure stages of

ejector unless the increase is significant (>25%).

a multistage system, up to the pressure level where

& Besides wasting steam, excess motive pressure tends

condensers are effective with available cooling water

to choke the venturi with steam, thereby decreasing

temperatures.

the suction capacity of the ejector.

. What are the factors that are to be considered in the

& The performance of ejectors designed for saturated

selection of an ejector?

steam will be adversely affected if operated with

& The selection of an ejector for a given application

superheated steam.

depends upon available steam pressure, maximum

& The specific volume of steam increases with increas-

water temperature, highest vacuum, temperature, and

ing temperature, which may require an increase in

capacity required.

pressure to maintain required steam flow.

. What are the factors that influence performance of

& Excess moisture in steam is one of the most common

ejectors?

problems found in ejectors. Wet steam causes poor

& The performance of an ejector is afunction of the area

performance and, depending on the degree of wet-

of the motive fluid nozzle and venturi throat, pressure

ness, can permanently damage an ejector in a very

of the motive fluid, suction and discharge pressures,

short period of time. A steam quality of less than 2%

ratios of specific heats, molecular weights, and

moisture is tolerable with most moderate vacuum

temperatures.