Page 293 - Fluid-Structure Interactions Slender Structure and Axial Flow (Volume 1)

P. 293

274 SLENDER STRUCTURES AND AXIAL FLOW

Harmonic loading

Bending deformation (with damping)

( deformation (with damping) (with phase diferences)

In

Elastic Axial plug Rigid Distributed Concentrated Prescibed

clamping flow body support with support with support

damping damping motion

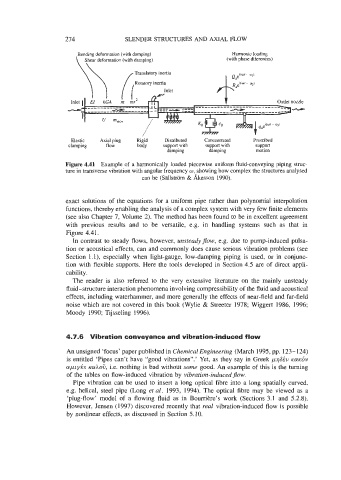

Figure 4.41 Example of a harmonically loaded piecewise uniform fluid-conveying piping struc-

ture in transverse vibration with angular frequency w, showing how complex the structures analysed

can be (Siillstrom & Akesson 1990).

exact solutions of the equations for a uniform pipe rather than polynomial interpolation

functions, thereby enabling the analysis of a complex system with very few finite elements

(see also Chapter 7, Volume 2). The method has been found to be in excellent agreement

with previous results and to be versatile, e.g. in handling systems such as that in

Figure 4.41.

In contrast to steady flows, however, unsteady jow, e.g. due to pump-induced pulsa-

tion or acoustical effects, can and commonly does cause serious vibration problems (see

Section 1. l), especially when light-gauge, low-damping piping is used, or in conjunc-

tion with flexible supports. Here the tools developed in Section 4.5 are of direct appli-

cability.

The reader is also referred to the very extensive literature on the mainly unsteady

fluid-structure interaction phenomena involving compressibility of the fluid and acoustical

effects, including waterhammer, and more generally the effects of near-field and far-field

noise which are not covered in this book (Wylie & Streeter 1978; Wiggert 1986, 1996;

Moody 1990; Tijsseling 1996).

4.7.6 Vibration conveyance and vibration-induced flow

An unsigned ‘focus’ paper published in Chemical Engineering (March 1995, pp. 123- 124)

is entitled ‘Pipes can’t have “good vibrations”.’ Yet, as they say in Greek pqSi‘v KUK~Y

a~i K~AoG, i.e. nothing is bad without some good. An example of this is the turning

yks

of the tables on flow-induced vibration by vibration-inducedflow.

Pipe vibration can be used to insert a long optical fibre into a long spatially curved,

e.g. helical, steel pipe (Long et al. 1993, 1994). The optical fibre may be viewed as a

‘plug-flow’ model of a flowing fluid as in Bourrikre’s work (Sections 3.1 and 5.2.8).

However, Jensen (1 997) discovered recently that real vibration-induced flow is possible

by nonlinear effects, as discussed in Section 5.10.