Page 407 - Forensic Structural Engineering Handbook

P. 407

11.38 MATERIAL-SPECIFIC FORENSIC ANALYSES

(a) (b)

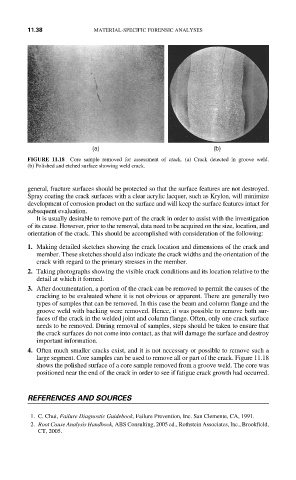

FIGURE 11.18 Core sample removed for assessment of crack. (a) Crack detected in groove weld.

(b) Polished and etched surface showing weld crack.

general, fracture surfaces should be protected so that the surface features are not destroyed.

Spray coating the crack surfaces with a clear acrylic lacquer, such as Krylon, will minimize

development of corrosion product on the surface and will keep the surface features intact for

subsequent evaluation.

It is usually desirable to remove part of the crack in order to assist with the investigation

of its cause. However, prior to the removal, data need to be acquired on the size, location, and

orientation of the crack. This should be accomplished with consideration of the following:

1. Making detailed sketches showing the crack location and dimensions of the crack and

member. These sketches should also indicate the crack widths and the orientation of the

crack with regard to the primary stresses in the member.

2. Taking photographs showing the visible crack conditions and its location relative to the

detail at which it formed.

3. After documentation, a portion of the crack can be removed to permit the causes of the

cracking to be evaluated where it is not obvious or apparent. There are generally two

types of samples that can be removed. In this case the beam and column flange and the

groove weld with backing were removed. Hence, it was possible to remove both sur-

faces of the crack in the welded joint and column flange. Often, only one crack surface

needs to be removed. During removal of samples, steps should be taken to ensure that

the crack surfaces do not come into contact, as that will damage the surface and destroy

important information.

4. Often much smaller cracks exist, and it is not necessary or possible to remove such a

large segment. Core samples can be used to remove all or part of the crack. Figure 11.18

shows the polished surface of a core sample removed from a groove weld. The core was

positioned near the end of the crack in order to see if fatigue crack growth had occurred.

REFERENCES AND SOURCES

1. C. Chui, Failure Diagnostic Guidebook, Failure Prevention, Inc. San Clemente, CA, 1991.

2. Root Cause Analysis Handbook, ABS Consulting, 2005 ed., Rothstein Associates, Inc., Brookfield,

CT, 2005.