Page 494 - Forensic Structural Engineering Handbook

P. 494

MASONRY STRUCTURES 13.39

permission for site visits, sample removal, and field testing is usually obtained easily.

Potential adversaries may wish to have their experts present during site visits, but experts for

adversaries should not communicate regarding any aspect of the investigation without their

clients’ permission. However, with such permission it is sometimes possible that technical

experts could come to an agreement on recommended remedial measures to settle a dispute.

Reconnaissance Site Visit. The purpose of a reconnaissance site visit is to get an initial

understanding of the problem and identify resources (workers, money, materials, and

machines) necessary for investigation. Prior to a reconnaissance site visit, construction con-

tract documents should be reviewed. This first site visit may be made with perhaps only an

aide and the client. During a reconnaissance site visit, the investigator should note qualita-

tively many of the items to be observed quantitatively later during a data collection site visit.

Both the investigating engineer and an attending contractor will need tools and equipment,

such as those listed in Table 13.12. The forensic engineer will usually provide for her or his

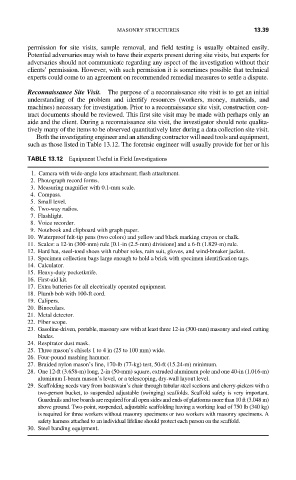

TABLE 13.12 Equipment Useful in Field Investigations

1. Camera with wide-angle lens attachment; flash attachment.

2. Photograph record forms.

3. Measuring magnifier with 0.1-mm scale.

4. Compass.

5. Small level.

6. Two-way radios.

7. Flashlight.

8. Voice recorder.

9. Notebook and clipboard with graph paper.

10. Waterproof felt-tip pens (two colors) and yellow and black marking crayon or chalk.

11. Scales: a 12-in (300-mm) rule [0.1-in (2.5-mm) divisions] and a 6-ft (1.829-m) rule.

12. Hard hat, steel-toed shoes with rubber soles, rain suit, gloves, and wind-breaker jacket.

13. Specimen collection bags large enough to hold a brick with specimen identification tags.

14. Calculator.

15. Heavy-duty pocketknife.

16. First-aid kit.

17. Extra batteries for all electrically operated equipment.

18. Plumb bob with 100-ft cord.

19. Calipers.

20. Binoculars.

21. Metal detector.

22. Fiber scope.

23. Gasoline-driven, portable, masonry saw with at least three 12-in (300-mm) masonry and steel cutting

blades.

24. Respirator dust mask.

25. Three mason’s chisels 1 to 4 in (25 to 100 mm) wide.

26. Four-pound mashing hammer.

27. Braided nylon mason’s line, 170-lb (77-kg) test, 50-ft (15.24-m) minimum.

28. One 12-ft (3.658-m) long, 2-in (50-mm) square, extruded aluminum pole and one 40-in (1.016-m)

aluminum I-beam mason’s level, or a telescoping, dry-wall layout level.

29. Scaffolding needs vary from boatswain’s chair through tubular steel sections and cherry-pickers with a

two-person bucket, to suspended adjustable (swinging) scaffolds. Scaffold safety is very important.

Guardrails and toe boards are required for all open sides and ends of platforms more than 10 ft (3.048 m)

above ground. Two-point, suspended, adjustable scaffolding having a working load of 750 lb (340 kg)

is required for three workers without masonry specimens or two workers with masonry specimens. A

safety harness attached to an individual lifeline should protect each person on the scaffold.

30. Steel banding equipment.