Page 497 - Forensic Structural Engineering Handbook

P. 497

13.42 MATERIAL-SPECIFIC FORENSIC ANALYSES

The in-place masonry shear test takes advantage of the modular nature of masonry to

allow the direct measurement of the shear resistance of an existing masonry wall. One unit,

either a brick or a block, is removed from the wall to make room for a hydraulic ram and

loading blocks to apply load to the end of an adjacent unit. The head joint opposite the

loaded end of the test unit is carefully excavated and cleared of mortar to provide space for

the test unit to move. The test unit is loaded by the ram until the bed joints fail and the unit

slides in the plane of the wall. 60

The International Existing Building Code, Appendix A1, Seismic Strengthening

Provisions for Unreinforced Masonry Bearing Wall Buildings, describes a shear testing of

existing masonry mortar and the number and locations of tests. American Society of Civil

64

Engineers (ASCE) 41, Seismic Rehabilitation of Buildings, also describes shear testing,

and provides a formula for expressing the expected masonry shear strength as a function of

shear test results. Both the IEBC and ASCE 41 reference the standard UBC 21-6, In-Place

Masonry Shear Tests, which is a concise two-paragraph description of the test. For those

requiring more detail, ASTM publishes a technically thorough description of this and sim-

ilar tests, ASTM C 1531, Standard Test Methods for In Situ Masonry Mortar Joints Shear

Strength Index. 63

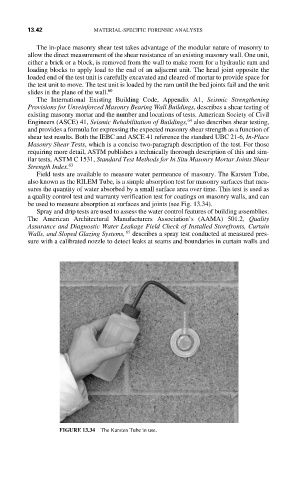

Field tests are available to measure water permeance of masonry. The Karsten Tube,

also known as the RILEM Tube, is a simple absorption test for masonry surfaces that mea-

sures the quantity of water absorbed by a small surface area over time. This test is used as

a quality control test and warranty verification test for coatings on masonry walls, and can

be used to measure absorption at surfaces and joints (see Fig. 13.34).

Spray and drip tests are used to assess the water control features of building assemblies.

The American Architectural Manufacturers Association’s (AAMA) 501.2, Quality

Assurance and Diagnostic Water Leakage Field Check of Installed Storefronts, Curtain

Walls, and Sloped Glazing Systems, 65 describes a spray test conducted at measured pres-

sure with a calibrated nozzle to detect leaks at seams and boundaries in curtain walls and

FIGURE 13.34 The Karsten Tube in use.