Page 78 - Formulas and Calculations for Petroleum Engineering

P. 78

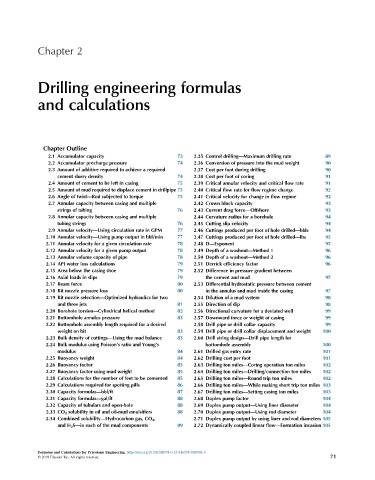

Chapter 2

Drilling engineering formulas

and calculations

Chapter Outline

2.1 Accumulator capacity 73 2.35 Control drilling—Maximum drilling rate 89

2.2 Accumulator precharge pressure 74 2.36 Conversion of pressure into the mud weight 90

2.3 Amount of additive required to achieve a required 2.37 Cost per foot during drilling 90

cement slurry density 74 2.38 Cost per foot of coring 91

2.4 Amount of cement to be left in casing 75 2.39 Critical annular velocity and critical flow rate 91

2.5 Amount of mud required to displace cement in drillpipe 75 2.40 Critical flow rate for flow regime change 92

2.6 Angle of twist—Rod subjected to torque 75 2.41 Critical velocity for change in flow regime 92

2.7 Annular capacity between casing and multiple 2.42 Crown block capacity 93

strings of tubing 76 2.43 Current drag force—Offshore 93

2.8 Annular capacity between casing and multiple 2.44 Curvature radius for a borehole 94

tubing strings 76 2.45 Cutting slip velocity 94

2.9 Annular velocity—Using circulation rate in GPM 77 2.46 Cuttings produced per foot of hole drilled—bbls 94

2.10 Annular velocity—Using pump output in bbl/min 77 2.47 Cuttings produced per foot of hole drilled—lbs 95

2.11 Annular velocity for a given circulation rate 78 2.48 D—Exponent 95

2.12 Annular velocity for a given pump output 78 2.49 Depth of a washout—Method 1 96

2.13 Annular volume capacity of pipe 78 2.50 Depth of a washout—Method 2 96

2.14 API water loss calculations 79 2.51 Derrick efficiency factor 96

2.15 Area below the casing shoe 79 2.52 Difference in pressure gradient between

2.16 Axial loads in slips 79 the cement and mud 97

2.17 Beam force 80 2.53 Differential hydrostatic pressure between cement

2.18 Bit nozzle pressure loss 80 in the annulus and mud inside the casing 97

2.19 Bit nozzle selection—Optimized hydraulics for two 2.54 Dilution of a mud system 98

and three jets 81 2.55 Direction of dip 98

2.20 Borehole torsion—Cylindrical helical method 82 2.56 Directional curvature for a deviated well 99

2.21 Bottomhole annulus pressure 83 2.57 Downward force or weight of casing 99

2.22 Bottomhole assembly length required for a desired 2.58 Drill pipe or drill collar capacity 99

weight on bit 83 2.59 Drill pipe or drill collar displacement and weight 100

2.23 Bulk density of cuttings—Using the mud balance 83 2.60 Drill string design—Drill pipe length for

2.24 Bulk modulus using Poisson’s ratio and Young’s bottomhole assembly 100

modulus 84 2.61 Drilled gas entry rate 101

2.25 Buoyancy weight 84 2.62 Drilling cost per foot 101

2.26 Buoyancy factor 85 2.63 Drilling ton miles—Coring operation ton miles 102

2.27 Buoyancy factor using mud weight 85 2.64 Drilling ton miles—Drilling/connection ton miles 102

2.28 Calculations for the number of feet to be cemented 85 2.65 Drilling ton miles—Round trip ton miles 102

2.29 Calculations required for spotting pills 86 2.66 Drilling ton miles—While making short trip ton miles 103

2.30 Capacity formulas—bbl/ft 87 2.67 Drilling ton miles—Setting casing ton miles 103

2.31 Capacity formulas—gal/ft 88 2.68 Duplex pump factor 104

2.32 Capacity of tubulars and open-hole 88 2.69 Duplex pump output—Using liner diameter 104

2.33 CO 2 solubility in oil and oil-mud emulsifiers 88 2.70 Duplex pump output—Using rod diameter 104

2.34 Combined solubility—Hydrocarbon gas, CO 2 , 2.71 Duplex pump output by using liner and rod diameters 105

and H 2 S—in each of the mud components 89 2.72 Dynamically coupled linear flow—Formation invasion 105

Formulas and Calculations for Petroleum Engineering. https://doi.org/10.1016/B978-0-12-816508-9.00002-0

© 2019 Elsevier Inc. All rights reserved. 71