Page 210 - T. Anderson-Fracture Mechanics - Fundamentals and Applns.-CRC (2005)

P. 210

1656_C004.fm Page 190 Thursday, April 21, 2005 5:38 PM

190 Fracture Mechanics: Fundamentals and Applications

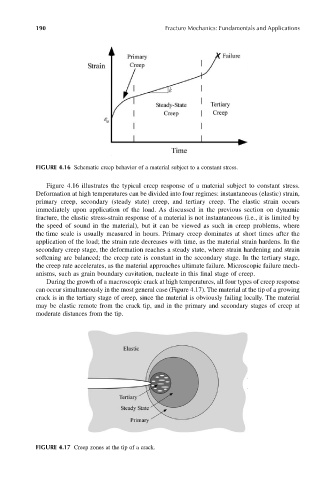

FIGURE 4.16 Schematic creep behavior of a material subject to a constant stress.

Figure 4.16 illustrates the typical creep response of a material subject to constant stress.

Deformation at high temperatures can be divided into four regimes: instantaneous (elastic) strain,

primary creep, secondary (steady state) creep, and tertiary creep. The elastic strain occurs

immediately upon application of the load. As discussed in the previous section on dynamic

fracture, the elastic stress-strain response of a material is not instantaneous (i.e., it is limited by

the speed of sound in the material), but it can be viewed as such in creep problems, where

the time scale is usually measured in hours. Primary creep dominates at short times after the

application of the load; the strain rate decreases with time, as the material strain hardens. In the

secondary creep stage, the deformation reaches a steady state, where strain hardening and strain

softening are balanced; the creep rate is constant in the secondary stage. In the tertiary stage,

the creep rate accelerates, as the material approaches ultimate failure. Microscopic failure mech-

anisms, such as grain boundary cavitation, nucleate in this final stage of creep.

During the growth of a macroscopic crack at high temperatures, all four types of creep response

can occur simultaneously in the most general case (Figure 4.17). The material at the tip of a growing

crack is in the tertiary stage of creep, since the material is obviously failing locally. The material

may be elastic remote from the crack tip, and in the primary and secondary stages of creep at

moderate distances from the tip.

FIGURE 4.17 Creep zones at the tip of a crack.