Page 228 - Fundamentals of Air Pollution

P. 228

V. Sampler Siting Requirements 191

where k is the permeation constant, C the concentration of gas in parts per

million, t the time of exposure, and m the amount of gas absorbed in

micrograms.

Permeation systems can be calibrated in the laboratory and then used in

the field for sample collection for a fixed period of time, e.g., 8 hr or 7

days. The sampler is returned to the laboratory for analysis. These systems

can be made for specific compounds by selecting the appropriate collection

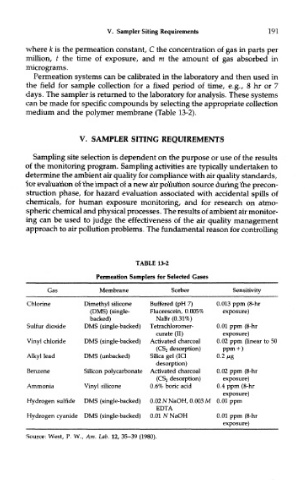

medium and the polymer membrane (Table 13-2).

V. SAMPLER SITING REQUIREMENTS

Sampling site selection is dependent on the purpose or use of the results

of the monitoring program. Sampling activities are typically undertaken to

determine the ambient air quality for compliance with air quality standards,

for evaluation of the impact of a new air pollution source during the precon-

struction phase, for hazard evaluation associated with accidental spills of

chemicals, for human exposure monitoring, and for research on atmo-

spheric chemical and physical processes. The results of ambient air monitor-

ing can be used to judge the effectiveness of the air quality management

approach to air pollution problems. The fundamental reason for controlling

TABLE 13-2

Permeation Samplers for Selected Gases

Gas Membrane Sorber Sensitivity

Chlorine Dimethyl silicone Buffered (pH 7) 0.013 ppm (8-hr

(DMS) (single- Fluorescein, 0.005% exposure)

backed) NaBr (0.31%)

Sulfur dioxide DMS (single-backed) Tetrachloromer- 0.01 ppm (8-hr

curate (II) exposure)

Vinyl chloride DMS (single-backed) Activated charcoal 0.02 ppm (linear to 50

(CS 2 desorption) ppm + )

Alkyl lead DMS (unbacked) Silica gel (IC1 0-2 /ig

desorption)

Benzene Silicon polycarbonate Activated charcoal 0.02 ppm (8-hr

(CS 2 desorption) exposure)

Ammonia Vinyl silicone 0.6% boric acid 0.4 ppm (8-hr

exposure)

Hydrogen sulfide DMS (single-backed) 0.02 NNaOH, 0.003 M 0.01 ppm

EDTA

Hydrogen cyanide DMS (single-backed) 0.01 N NaOH 0.01 ppm (8-hr

exposure)

Source: West, P, W.., Am. Lab. 12, 35-39 (1980).