Page 192 - Fundamentals of Gas Shale Reservoirs

P. 192

172 GEOMECHANICS OF GAS SHALES

80

70

60

50

1 – 3 (MPa) 40

30

1 2

20

3

10

v

0

–4 –2 0 2 4

(%)

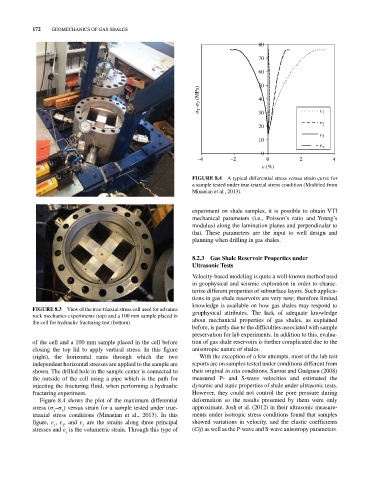

FIGURE 8.4 A typical differential stress versus strain curve for

a sample tested under true‐triaxial stress condition (Modified from

Minaeian et al., 2013).

experiment on shale samples, it is possible to obtain VTI

mechanical parameters (i.e., Poisson’s ratio and Young’s

modulus) along the lamination planes and perpendicular to

that. These parameters are the input to well design and

planning when drilling in gas shales.

8.2.3 Gas Shale Reservoir Properties under

Ultrasonic Tests

Velocity‐based modeling is quite a well‐known method used

in geophysical and seismic exploration in order to charac

terize different properties of subsurface layers. Such applica

tions in gas shale reservoirs are very new; therefore limited

knowledge is available on how gas shales may respond to

FIGURE 8.3 View of the true‐triaxial stress cell used for advance geophysical attributes. The lack of adequate knowledge

rock mechanics experiments (top) and a 100 mm sample placed in

the cell for hydraulic fracturing test (bottom). about mechanical properties of gas shales, as explained

before, is partly due to the difficulties associated with sample

preservation for lab experiments. In addition to this, evalua

of the cell and a 100 mm sample placed in the cell before tion of gas shale reservoirs is further complicated due to the

closing the top lid to apply vertical stress. In this figure anisotropic nature of shales.

(right), the horizontal rams through which the two With the exception of a few attempts, most of the lab test

independent horizontal stresses are applied to the sample are reports are on samples tested under conditions different from

shown. The drilled hole in the sample center is connected to their original in situ conditions. Sarout and Guéguen (2008)

the outside of the cell using a pipe which is the path for measured P‐ and S‐wave velocities and estimated the

injecting the fracturing fluid, when performing a hydraulic dynamic and static properties of shale under ultrasonic tests.

fracturing experiment. However, they could not control the pore pressure during

Figure 8.4 shows the plot of the maximum differential deformation so the results presented by them were only

stress (σ –σ ) versus strain for a sample tested under true‐ approximate. Josh et al. (2012) in their ultrasonic measure

1

3

triaxial stress conditions (Minaeian et al., 2013). In this ments under isotropic stress conditions found that samples

figure, ε , ε , and ε are the strains along three principal showed variations in velocity, and the elastic coefficients

3

1

2

stresses and ε is the volumetric strain. Through this type of (Cij) as well as the P‐wave and S‐wave anisotropy parameters.

v