Page 243 - Gas Purification 5E

P. 243

Mechanical Design and Operation of Alkanolamine Plants 229

(1980) recommend antifoam batch addition concentrations of 10 to 300 ppm. Manning and

Thompson (1991) recommend the following antifoams for amine systems:

Dow Coming DB-100 Antifoam Compound

Dow Coming DB-3 1 Antifoam Emulsion

Tretolite VEZ D-83

Tretolite D-95

. Natco DF-971

Exxon Corrects-It for chlorides

Union Carbide SAG Antifoams (GT-101, 102,301, or 302)

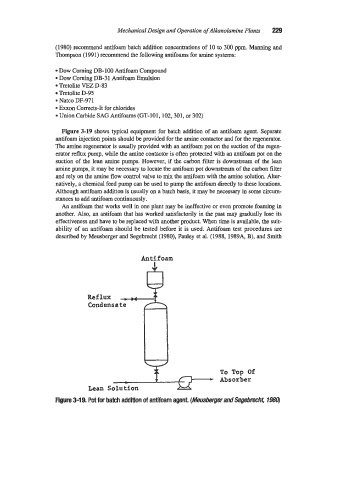

Figure 3-19 shows typical equipment for batch addition of an antifoam agent. Separate

antifoam injection points should be provided for the amine contactor and for the regenerator.

The amine regenerator is usually provided with an antifoam pot on the suction of the regen-

erator reflux pump, while the amine contactor is often protected with an antifoam pot on the

suction of the lean amine pumps. However, if the carbon filter is downstream of the lean

amine pumps, it may be necessary to locate the antifoam pot downstream of the carbon filter

and rely on the amine flow control valve to mix the antifoam with the amine solution. Alter-

natively, a chemical feed pump can be used to pump the antifoam directly to these locations.

Although antifoam addition is usually on a batch basis, it may be necessary in some circum-

stances to add antifoam continuously.

An antifoam that works well in one plant may be ineffective or even promote foaming in

another. Also, an antifoam that has worked satisfactorily in the past may gradually lose its

effectiveness and have to be replaced with another product. When time is available, the suit-

ability of an antifoam should be tested before it is used. Antifoam test procedures are

described by Meusberger and Segebrecht (1980), Pauley et al. (1988, 1989A, B), and Smith

Q

Antif oam

----La- To Top Of

Absorber

Lean Solution

Figure 3-19. Pot for batch addition of antifoam agent (MeW@erandSegebrecht, 198g