Page 263 - Gas Purification 5E

P. 263

248 Gas PuriJication

separated by internal bypasses which let unfiltered amine solution flow to the next layer. It is

claimed that the multiple layers of filtration media provide 15 times more capacity than a

string-wound cartridge and more than 7 times the capacity of a conventional bag filter

(Anon., 1989). Since one bag filter is equivalent to 15 string-wound cartridge filters, consid-

erable operating labor savings can be achieved during a filter element changeout. Ease of

replacement can enhance operator acceptance, and disposal costs are also often less for bag

filters due to their comparatively smaller volume.

Etched Disk and Sintered Metal Fiber Filters

Either cartridge or bag filters are usually acceptable for small to medium amine systems;

however, larger systems (1,000 gpm or greater amine circulation or more than about 100

LT/day of sulfur production) may require considerable operating labor per filter element

changeout. Operator acceptance of cartridges and bag filters in these larger systems is also

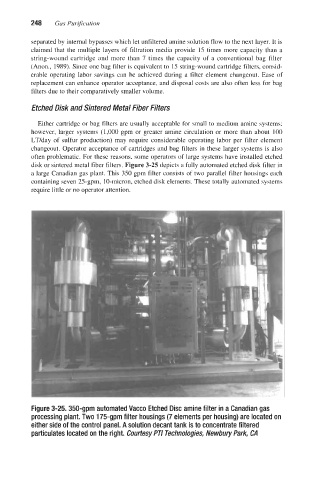

often problematic. For these reasons, some operators of large systems have installed etched

disk or sintered metal fiber filters. Figure 3-25 depicts a fully automated etched disk filter in

a large Canadian gas plant. This 350 gpm filter consists of two parallel filter housings each

containing seven 25-gpm, 10-micron, etched disk elements. These totally automated systems

require little or no operator attention.

Figure 3-25.350-gpm automated Vacco Etched Disc amine filter in a Canadian gas

processing plant. Two 175-gpm filter housings (7 elements per housing) are located on

either side of the control panel. A solution decant tank is to concentrate filtered

particulates located on the right. Courtesy PTl Technologies, Newbury Park, CA