Page 51 - Gas Purification 5E

P. 51

Alkanolarnines for Hydrogen Surfide and Carbon Dioxide Removal 41

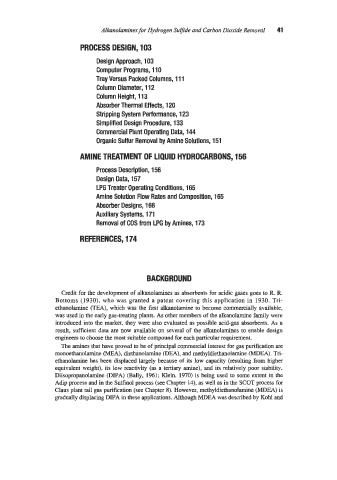

PROCESS DESIGN, 103

Design Approach, 103

Computer Programs, 110

Tray Versus Packed Columns, 11 1

Column Diameter, 11 2

Column Height, 11 3

Absorber Thermal Effects, 120

Stripping System Performance, 123

Simplified Design Procedure, 133

Commercial Plant Operating Data, 144

Organic Sulfur Removal by Amine Solutions, 151

AMINE TREATMENT OF LIQUID HYDROCARBONS, 156

Process Description, 156

Design Data, 157

LPG Treater Operating Conditions, 165

Amine Solution Flow Rates and Composition, 165

Absorber Designs, 166

Auxiliary Systems, 171

Removal of COS from LPG by Amines, 173

REFERENCES, 174

BACKGROUND

Credit for the development of alkanolamines as absorbents for acidic gases goes to R. R.

Bottoms j1930), who was granted a patent covering this application in 1930. Tri-

ethanolamine (TEA), which was the first alkanolamine to become commercially available,

was used in the early gas-treating plants. As other members of the alkanolamine family were

introduced into the market, they were also evaluated as possible acid-gas absorbents. As a

result, sufficient data are now available on several of the alkanolamines to enable design

engineers to choose the most suitable compound for each particular requirement.

The amines that have proved to be of principal commercial interest for gas purification are

monoethanolamine (MEA), diethanolamine (DEA)? and methyldiethanolamine (MDEA). Tri-

ethanolamine has been displaced largely because of its low capacity (resulting from higher

equivalent weight), its low reactivity (as a tertiary amine), and its relatively poor stability.

Diisopropanolamine (DIPA) (Bally, 1961; Klein, 1970) is being used to some extent in the

Adip process and in the Sulfinol process (see Chapter 14), as well as in the SCOT process for

Claw plant tail gas purification (see Chapter 8). However, methyldiethanolamine (JviDEA) is

gradually displacing DIPA in these applications. Although MDEA was described by Kohl and