Page 237 - Gas Wettability of Reservoir Rock Surfaces with Porous Media

P. 237

Application of Gas Wettability CHAPTER 6 221

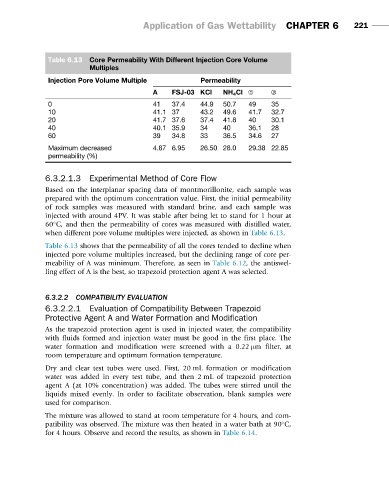

Table 6.13 Core Permeability With Different Injection Core Volume

Multiples

Injection Pore Volume Multiple Permeability

A FSJ-03 KCl NH 4 Cl ② ③

0 41 37.4 44.9 50.7 49 35

10 41.1 37 43.2 49.6 41.7 32.7

20 41.7 37.6 37.4 41.8 40 30.1

40 40.1 35.9 34 40 36.1 28

60 39 34.8 33 36.5 34.6 27

Maximum decreased 4.87 6.95 26.50 28.0 29.38 22.85

permeability (%)

6.3.2.1.3 Experimental Method of Core Flow

Based on the interplanar spacing data of montmorillonite, each sample was

prepared with the optimum concentration value. First, the initial permeability

of rock samples was measured with standard brine, and each sample was

injected with around 4PV. It was stable after being let to stand for 1 hour at

60 C, and then the permeability of cores was measured with distilled water,

when different pore volume multiples were injected, as shown in Table 6.13.

Table 6.13 shows that the permeability of all the cores tended to decline when

injected pore volume multiples increased, but the declining range of core per-

meability of A was minimum. Therefore, as seen in Table 6.12, the antiswel-

ling effect of A is the best, so trapezoid protection agent A was selected.

6.3.2.2 COMPATIBILITY EVALUATION

6.3.2.2.1 Evaluation of Compatibility Between Trapezoid

Protective Agent A and Water Formation and Modification

As the trapezoid protection agent is used in injected water, the compatibility

with fluids formed and injection water must be good in the first place. The

water formation and modification were screened with a 0.22 μm filter, at

room temperature and optimum formation temperature.

Dry and clear test tubes were used. First, 20 mL formation or modification

water was added in every test tube, and then 2 mL of trapezoid protection

agent A (at 10% concentration) was added. The tubes were stirred until the

liquids mixed evenly. In order to facilitate observation, blank samples were

used for comparison.

The mixture was allowed to stand at room temperature for 4 hours, and com-

patibility was observed. The mixture was then heated in a water bath at 90 C,

for 4 hours. Observe and record the results, as shown in Table 6.14.