Page 266 - Gas Wettability of Reservoir Rock Surfaces with Porous Media

P. 266

250 Gas Wettability of Reservoir Rock Surfaces with Porous Media

Oily cuttings or sludge

Adding degreaser

Chemical Residue

Oil recovery

cleaning treatment

Adding hardening agent

Wastewater

Solidification

disposal

Flocculant oxidizing agent

Flocculation Leachate test

oxidation

Standardized

Wastewater test

discharge

Standardized

discharge

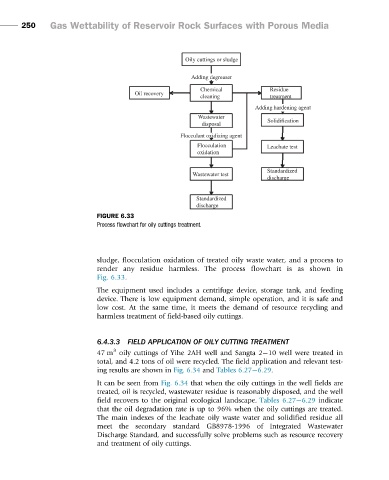

FIGURE 6.33

Process flowchart for oily cuttings treatment.

sludge, flocculation oxidation of treated oily waste water, and a process to

render any residue harmless. The process flowchart is as shown in

Fig. 6.33.

The equipment used includes a centrifuge device, storage tank, and feeding

device. There is low equipment demand, simple operation, and it is safe and

low cost. At the same time, it meets the demand of resource recycling and

harmless treatment of field-based oily cuttings.

6.4.3.3 FIELD APPLICATION OF OILY CUTTING TREATMENT

3

47 m oily cuttings of Yihe 2AH well and Sangta 2 10 well were treated in

total, and 4.2 tons of oil were recycled. The field application and relevant test-

ing results are shown in Fig. 6.34 and Tables 6.27 6.29.

It can be seen from Fig. 6.34 that when the oily cuttings in the well fields are

treated, oil is recycled, wastewater residue is reasonably disposed, and the well

field recovers to the original ecological landscape. Tables 6.27 6.29 indicate

that the oil degradation rate is up to 96% when the oily cuttings are treated.

The main indexes of the leachate oily waste water and solidified residue all

meet the secondary standard GB8978-1996 of Integrated Wastewater

Discharge Standard, and successfully solve problems such as resource recovery

and treatment of oily cuttings.