Page 263 - Gas Wettability of Reservoir Rock Surfaces with Porous Media

P. 263

Application of Gas Wettability CHAPTER 6 247

b. 40 mL of degreaser solution of 1000 mg/L concentration each were

prepared and added separately into two centrifuge tubes.

c. The centrifuge tubes were then placed in a centrifuge machine. The

centrifuge rotational speed was 1500 r/min, time of rotation was 5

minutes, and the centrifugal treatment was conducted at 25 C experi-

mental temperature.

d. The waste liquor in the centrifuge tubes was poured into a waste

liquor storage tank. The residue was put in glass vessels for air-drying

and complete grinding.

e. The oil content of the residue was measured with the method mea-

suring the oil content of degreased oily cuttings, and the experimen-

tal oil degradation rate of each group was calculated. The

experimental result is shown in Table 6.23.

It can be seen from Table 6.23 that the oil degradation rate of oily

cuttings is 87.09%, and the oil degradation rate of oily sludge is

91.08%. This illustrates that the degreaser possesses good degreasing

capability for oily cuttings and oily sludge.

3. The relationship between the concentration of degreasing agent and oil

removal rate

The oil degradation effects of the degreaser were evaluated under dif-

ferent concentrations and dosage, as shown in Table 6.24. The

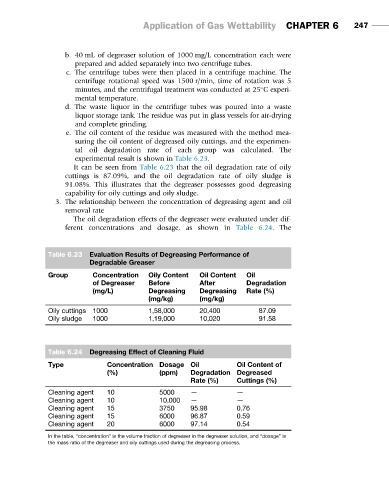

Table 6.23 Evaluation Results of Degreasing Performance of

Degradable Greaser

Group Concentration Oily Content Oil Content Oil

of Degreaser Before After Degradation

(mg/L) Degreasing Degreasing Rate (%)

(mg/kg) (mg/kg)

Oily cuttings 1000 1,58,000 20,400 87.09

Oily sludge 1000 1,19,000 10,020 91.58

Table 6.24 Degreasing Effect of Cleaning Fluid

Type Concentration Dosage Oil Oil Content of

(%) (ppm) Degradation Degreased

Rate (%) Cuttings (%)

Cleaning agent 10 5000 — —

Cleaning agent 10 10,000 — —

Cleaning agent 15 3750 95.98 0.76

Cleaning agent 15 6000 96.87 0.59

Cleaning agent 20 6000 97.14 0.54

In the table, “concentration” is the volume fraction of degreaser in the degreaser solution, and “dosage” is

the mass ratio of the degreaser and oily cuttings used during the degreasing process.