Page 108 - Geochemistry of Oil Field Waters

P. 108

96 ANALYSIS OF OILFIELD WATERS

Acidifying the samples to pH 3.5 with acetic or hydrochloric acid

minimizes precipitation and adsorption. If acetic acid is used, 2 ml of formal-

dehyde per liter of sample should be added to retard mold growth. These

precautions will aid in obtaining representative heavy metal analyses; how-

ever, to obtain optimum results, the samples should be analyzed as quickly

after sampling as possible. If it is necessary to store the samples, they should

be stored in a cool, dark place and should not be moved frequently. Light

accelerates photochemical reactions, and high temperatures and moving

accelerate chemical reactions. Once the seal of the cap of the sample bottle

has been broken, the sample should be analyzed immediately.

A chelating ion-exchange resin such as Dowex A-1 can be used to separate

copper, iron, nickel, and lead from an aqueous solution. Slurry the resin into

a plastic column about 36 cm long and 1.7 cm in diameter. Convert the resin

to the sodium form by washing with 2 volumes of distilled water, 1 volume

being equal to the amount of resin used, followed by 2 volumes of 1N

sodium hydroxide, and then with 10 volumes of distilled water. Because the

resin expands more than 100% when changing from the hydrogen form to

the sodium form, the column must be backwashed frequently to reduce

compaction of the resin and to prevent shattering of the column. Pass the

brine which has been neutralized to pH 7.0 with sodium hydroxide through

the column. 2 liters or more probably will be necessary, depending upon the

amount of heavy metals present in the brine. Elute the chelated metals with

2 volumes of 2N hydrochloric acid and water effluents to a small volume;

cool and adjust to a predetermined volume (for example, 200 ml) with

water. Use aliquots of this solution for determining copper, iron, nickel, and

lead.

The resin must be changed back to the sodium form as soon as the metals

have been eluted, because the resin tends to lose its chelating capacity if left

in the water-rinsed hydrogen form for longer than a few hours. If this

happens, the resin can be regenerated by heating it at 6OoC in a 30-50%

sodium hydroxide solution for 24 hours.

Once the metals are separated from the brine and concentrated, they can

be analyzed using various methods such as atomic absorption spectrometry,

flame spectrometry, emission spectrometry, or colorimetry (Collins et al.,

1962).

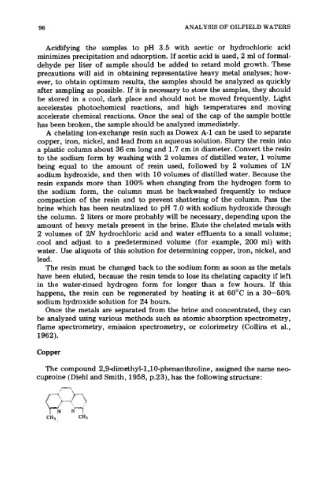

The compound 2,9-dimethyl-1 ,lo-phenanthroline, assigned the name neo-

cuproine (Diehl and Smith, 1958, p.23), has the following structure: