Page 23 - Geochemistry of Oil Field Waters

P. 23

12 SAMPLING SUBSURFACE OILFIELD WATERS

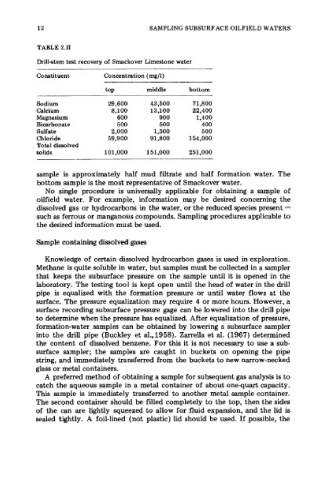

TABLE 2.11

Drill-stem test recovery of Smackover Limestone water

Constituent Concentration (mg/l)

top middle bottom

-

Sodium 29,600 43,500 71,800

Calcium 8,100 13,100 22,400

Magnesium 600 900 1,400

Bicarbonate 500 500 400

Sulfate 2,000 1,300 500

Chloride 59,900 91,800 154,000

Total dissolved

solids 101,000 151,000 251,000

sample is approximately half mud filtrate and half formation water. The

bottom sample is the most representative of Smackover water.

No single procedure is universally applicable for obtaining a sample of

oilfield water. For example, information may be desired concerning the

dissolved gas or hydrocarbons in the water, or the reduced species present -

such as ferrous or manganous compounds. Sampling procedures applicable to

the desired information must be used.

Sample containing dissolved gases

Knowledge of certain dissolved hydrocarbon gases is used in exploration.

Methane is quite soluble in water, but samples must be collected in a sampler

that keeps the subsurface pressure on the sample until it is opened in the

laboratory. The testing tool is kept open until the head of water in the drill

pipe is equalized with the formation pressure or until water flows at the

surface. The pressure equalization may require 4 or more hours. However, a

surface recording subsurface pressure gage can be lowered into the drill pipe

to determine when the pressure has equalized. After equalization of pressure,

formation-water samples can be obtained by lowering a subsurface sampler

into the drill pipe (Buckley et al.,1958). Zarrella et al. (1967) determined

the content of dissolved benzene. For this it is not necessary to use a sub-

surface sampler; the samples are caught in buckets on opening the pipe

string, and immediately transferred from the buckets to new narrow-necked

glass or metal containers.

A preferred method of obtaining a sample for subsequent gas analysis is to

catch the aqueous sample in a metal container of about one-quart capacity.

This sample is immediately transferred to another metal sample container.

The second container should be filled completely to the top, then the sides

of the can are lightly squeezed to allow for fluid expansion, and the lid is

sealed tightly. A foil-lined (not plastic) lid should be used. If possible, the