Page 146 - Geothermal Energy Systems Exploration, Development, and Utilization

P. 146

122 3 Drilling into Geothermal Reservoirs

3.2.3

Directional Drilling

Directional drilling is done if a borehole has to be steered into a specific direction

and/or into a target. It also allows drilling several wells from one single site into

different targets. To implement directional drilling, special equipment such as

those listed and described below is needed.

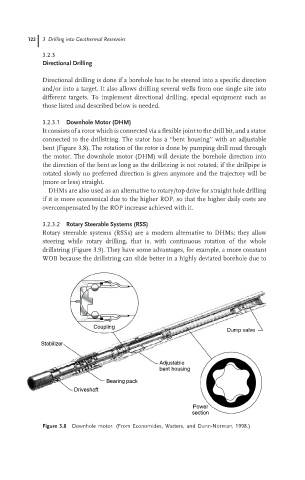

3.2.3.1 Downhole Motor (DHM)

It consists of a rotor which is connected via a flexible joint to the drill bit, and a stator

connected to the drillstring. The stator has a ‘‘bent housing’’ with an adjustable

bent (Figure 3.8). The rotation of the rotor is done by pumping drill mud through

the motor. The downhole motor (DHM) will deviate the borehole direction into

the direction of the bent as long as the drillstring is not rotated; if the drillpipe is

rotated slowly no preferred direction is given anymore and the trajectory will be

(more or less) straight.

DHMs are also used as an alternative to rotary/top drive for straight hole drilling

if it is more economical due to the higher ROP, so that the higher daily costs are

overcompensated by the ROP increase achieved with it.

3.2.3.2 Rotary Steerable Systems (RSS)

Rotary steerable systems (RSSs) are a modern alternative to DHMs; they allow

steering while rotary drilling, that is, with continuous rotation of the whole

drillstring (Figure 3.9). They have some advantages, for example, a more constant

WOB because the drillstring can slide better in a highly deviated borehole due to

Coupling

Dump valve

Stabilizer

Adjustable

bent housing

Bearing pack

Driveshaft

Power

section

Figure 3.8 Downhole motor. (From Economides, Watters, and Dunn-Norman, 1998.)