Page 233 - Geothermal Energy Systems Exploration, Development, and Utilization

P. 233

4.9 Sustainability of Treatment 209

W

s eff

Proppant

crushing,

Formation

compaction

X f

Filtrate invasion,

filter cake

(fracture face damage)

Rock detritus

(mechanical

erosion and fines

migration during

fracture creation)

Proppant

Gel residues,

chemical precipitates s eff

Proppant

embedment zone

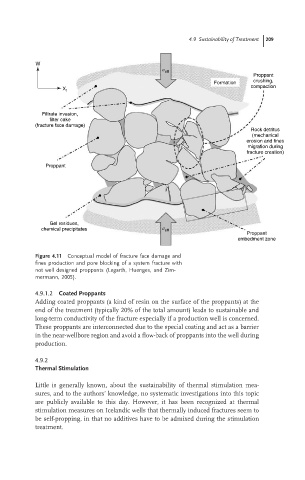

Figure 4.11 Conceptual model of fracture face damage and

fines production and pore blocking of a system fracture with

not well designed proppants (Legarth, Huenges, and Zim-

mermann, 2005).

4.9.1.2 Coated Proppants

Adding coated proppants (a kind of resin on the surface of the proppants) at the

end of the treatment (typically 20% of the total amount) leads to sustainable and

long-term conductivity of the fracture especially if a production well is concerned.

These proppants are interconnected due to the special coating and act as a barrier

in the near-wellbore region and avoid a flow-back of proppants into the well during

production.

4.9.2

Thermal Stimulation

Little is generally known, about the sustainability of thermal stimulation mea-

sures, and to the authors’ knowledge, no systematic investigations into this topic

are publicly available to this day. However, it has been recognized at thermal

stimulation measures on Icelandic wells that thermally induced fractures seem to

be self-propping, in that no additives have to be admixed during the stimulation

treatment.