Page 238 - Geothermal Energy Systems Exploration, Development, and Utilization

P. 238

214 4 Enhancing Geothermal Reservoirs

TVD

4000

3

500 m gel (YF140/145) + 4% KCl

113 t proppant (HSP 20/40 coated/uncoated)

4100 P max = 495 bar −1

4100 Q max = 58 liter sec .

3

500 m gel (YF140/145) + 4% KCl

4200 95 t proppant (HSP 20/40 coated/uncoated)

Sandstones

P max = 380 bar −1

Q max = 66 liter sec .

Conglomerates

4300 3

13000 m water (pH5)

4374 24 t sand

4200 Volcanics P max = 586 bar −1

Q max = 150 liter sec .

4400

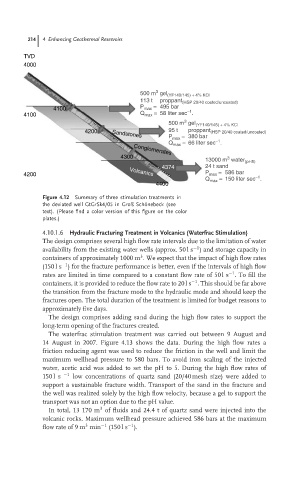

Figure 4.12 Summary of three stimulation treatments in

the deviated well GtGrSk4/05 in Groß Sch¨onebeck (see

text). (Please find a color version of this figure on the color

plates.)

4.10.1.6 Hydraulic Fracturing Treatment in Volcanics (Waterfrac Stimulation)

The design comprises several high flow rate intervals due to the limitation of water

−1

availability from the existing water wells (approx. 50 l s ) and storage capacity in

3

containers of approximately 1000 m . We expect that the impact of high flow rates

−1

(150 l s ) for the fracture performance is better, even if the intervals of high flow

−1

rates are limited in time compared to a constant flow rate of 50 l s . To fill the

−1

containers, it is provided to reduce the flow rate to 20 l s . This should be far above

the transition from the fracture mode to the hydraulic mode and should keep the

fractures open. The total duration of the treatment is limited for budget reasons to

approximately five days.

The design comprises adding sand during the high flow rates to support the

long-term opening of the fractures created.

The waterfrac stimulation treatment was carried out between 9 August and

14 August in 2007. Figure 4.13 shows the data. During the high flow rates a

friction reducing agent was used to reduce the friction in the well and limit the

maximum wellhead pressure to 580 bars. To avoid iron scaling of the injected

water, acetic acid was added to set the pH to 5. During the high flow rates of

150 l s −1 low concentrations of quartz sand (20/40 mesh size) were added to

support a sustainable fracture width. Transport of the sand in the fracture and

the well was realized solely by the high flow velocity, because a gel to support the

transport was not an option due to the pH value.

3

In total, 13 170 m of fluids and 24.4 t of quartz sand were injected into the

volcanic rocks. Maximum wellhead pressure achieved 586 bars at the maximum

3

−1

flow rate of 9 m min −1 (150 l s ).