Page 252 - Handbook of Thermal Analysis of Construction Materials

P. 252

234 Chapter 6 - Retarding and Water Reducing Admixtures

Conduction calorimetric curves also demonstrate the retarding

effect of lignosulfonate on cement. [18] Conduction calorimetric curves of

cement containing 0, 0.1, 0.3, and 0.5% CLS show that the cement containing

CLS delays the appearance of the peaks caused by the C S phase.

3

Odler and Becker followed the DTA behavior of high early strength

cement and a laboratory-made cement containing 0.5% lignosulfonate.

They were hydrated for different periods. [12] Thermograms indicated that

the formation of ettringite was accelerated in the commercial cement while

it was retarded in the laboratory cement. The rate of formation of Ca(OH) 2

was significantly lower in both cements containing the lignosulfonate

admixture.

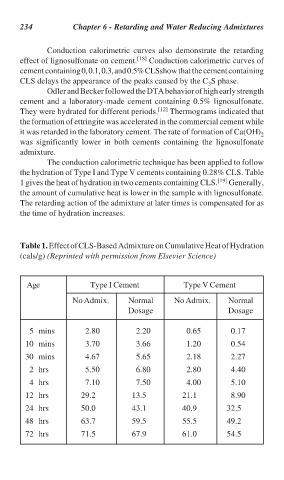

The conduction calorimetric technique has been applied to follow

the hydration of Type I and Type V cements containing 0.28% CLS. Table

1 gives the heat of hydration in two cements containing CLS. [19] Generally,

the amount of cumulative heat is lower in the sample with lignosulfonate.

The retarding action of the admixture at later times is compensated for as

the time of hydration increases.

Table 1. Effect of CLS-Based Admixture on Cumulative Heat of Hydration

(cals/g) (Reprinted with permission from Elsevier Science)

Age Type I Cement Type V Cement

No Admix. Normal No Admix. Normal

Dosage Dosage

5 mins 2.80 2.20 0.65 0.17

10 mins 3.70 3.66 1.20 0.54

30 mins 4.67 5.65 2.18 2.27

2 hrs 5.50 6.80 2.80 4.40

4 hrs 7.10 7.50 4.00 5.10

12 hrs 29.2 13.5 21.1 8.90

24 hrs 50.0 43.1 40.9 32.5

48 hrs 63.7 59.5 55.5 49.2

72 hrs 71.5 67.9 61.0 54.5