Page 307 - Handbook of Thermal Analysis of Construction Materials

P. 307

284 Chapter 7 - Superplasticizing Admixtures

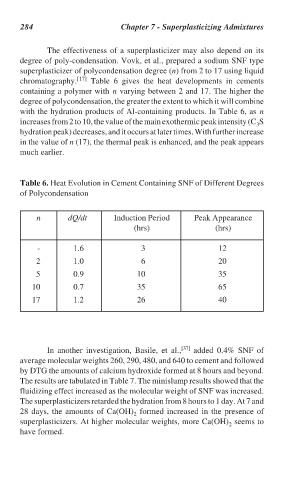

The effectiveness of a superplasticizer may also depend on its

degree of poly-condensation. Vovk, et al., prepared a sodium SNF type

superplasticizer of polycondensation degree (n) from 2 to 17 using liquid

chromatography. [17] Table 6 gives the heat developments in cements

containing a polymer with n varying between 2 and 17. The higher the

degree of polycondensation, the greater the extent to which it will combine

with the hydration products of Al-containing products. In Table 6, as n

increases from 2 to 10, the value of the main exothermic peak intensity (C S

3

hydration peak) decreases, and it occurs at later times. With further increase

in the value of n (17), the thermal peak is enhanced, and the peak appears

much earlier.

Table 6. Heat Evolution in Cement Containing SNF of Different Degrees

of Polycondensation

n dQ/dt Induction Period Peak Appearance

(hrs) (hrs)

- 1.6 3 12

2 1.0 6 20

5 0.9 10 35

10 0.7 35 65

17 1.2 26 40

In another investigation, Basile, et al., [37] added 0.4% SNF of

average molecular weights 260, 290, 480, and 640 to cement and followed

by DTG the amounts of calcium hydroxide formed at 8 hours and beyond.

The results are tabulated in Table 7. The minislump results showed that the

fluidizing effect increased as the molecular weight of SNF was increased.

The superplasticizers retarded the hydration from 8 hours to 1 day. At 7 and

28 days, the amounts of Ca(OH) formed increased in the presence of

2

superplasticizers. At higher molecular weights, more Ca(OH) seems to

2

have formed.