Page 350 - Handbook of Thermal Analysis of Construction Materials

P. 350

Section 6.0 - Metakaolinite 327

polymer formation which is responsible for strength development. A

shoulder also appears corresponding to a zeolite crystallization process. [67]

In DTA, an endothermal peak appearing at 165–175°C is attributed to the

process of dehydroxylation of the amorphous and crystalline zeolite. [68]

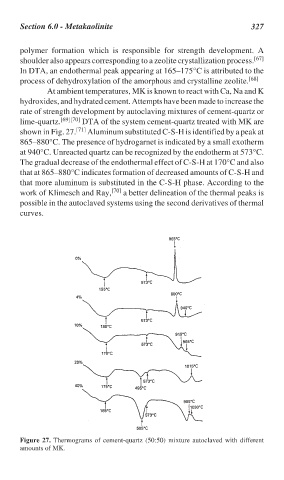

At ambient temperatures, MK is known to react with Ca, Na and K

hydroxides, and hydrated cement. Attempts have been made to increase the

rate of strength development by autoclaving mixtures of cement-quartz or

lime-quartz. [69][70] DTA of the system cement-quartz treated with MK are

shown in Fig. 27. [71] Aluminum substituted C-S-H is identified by a peak at

865–880°C. The presence of hydrogarnet is indicated by a small exotherm

at 940°C. Unreacted quartz can be recognized by the endotherm at 573°C.

The gradual decrease of the endothermal effect of C-S-H at 170°C and also

that at 865–880°C indicates formation of decreased amounts of C-S-H and

that more aluminum is substituted in the C-S-H phase. According to the

work of Klimesch and Ray, [70] a better delineation of the thermal peaks is

possible in the autoclaved systems using the second derivatives of thermal

curves.

Figure 27. Thermograms of cement-quartz (50:50) mixture autoclaved with different

amounts of MK.