Page 404 - Handbook of Thermal Analysis of Construction Materials

P. 404

382 Chapter 9 - Non-Portland Cement Binders and Concrete

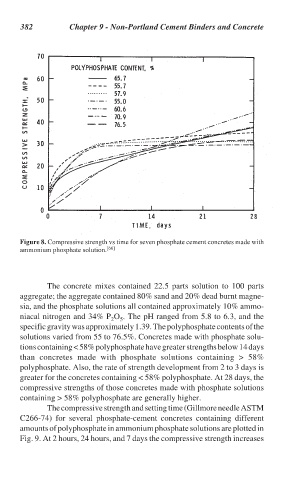

Figure 8. Compressive strength vs time for seven phosphate cement concretes made with

ammonium phosphate solution. [66]

The concrete mixes contained 22.5 parts solution to 100 parts

aggregate; the aggregate contained 80% sand and 20% dead burnt magne-

sia, and the phosphate solutions all contained approximately 10% ammo-

niacal nitrogen and 34% P O . The pH ranged from 5.8 to 6.3, and the

2 5

specific gravity was approximately 1.39. The polyphosphate contents of the

solutions varied from 55 to 76.5%. Concretes made with phosphate solu-

tions containing < 58% polyphosphate have greater strengths below 14 days

than concretes made with phosphate solutions containing > 58%

polyphosphate. Also, the rate of strength development from 2 to 3 days is

greater for the concretes containing < 58% polyphosphate. At 28 days, the

compressive strengths of those concretes made with phosphate solutions

containing > 58% polyphosphate are generally higher.

The compressive strength and setting time (Gillmore needle ASTM

C266-74) for several phosphate-cement concretes containing different

amounts of polyphosphate in ammonium phosphate solutions are plotted in

Fig. 9. At 2 hours, 24 hours, and 7 days the compressive strength increases