Page 428 - Handbook of Thermal Analysis of Construction Materials

P. 428

Section 2.0 - Calcium Aluminate Cements 405

2.2 Thermal Analysis of Hydrated Calcium Aluminate

Cements

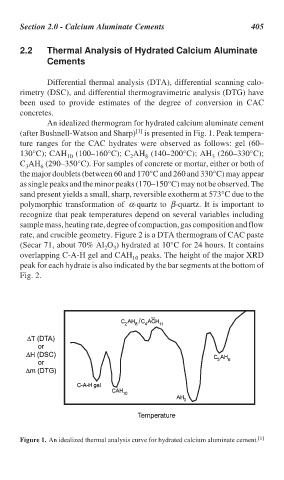

Differential thermal analysis (DTA), differential scanning calo-

rimetry (DSC), and differential thermogravimetric analysis (DTG) have

been used to provide estimates of the degree of conversion in CAC

concretes.

An idealized thermogram for hydrated calcium aluminate cement

[1]

(after Bushnell-Watson and Sharp) is presented in Fig. 1. Peak tempera-

ture ranges for the CAC hydrates were observed as follows: gel (60–

130°C); CAH (100–160°C); C AH (140–200°C); AH (260–330°C);

3

8

2

10

C AH (290–350°C). For samples of concrete or mortar, either or both of

3 6

the major doublets (between 60 and 170°C and 260 and 330°C) may appear

as single peaks and the minor peaks (170–150°C) may not be observed. The

sand present yields a small, sharp, reversible exotherm at 573°C due to the

polymorphic transformation of α-quartz to β-quartz. It is important to

recognize that peak temperatures depend on several variables including

sample mass, heating rate, degree of compaction, gas composition and flow

rate, and crucible geometry. Figure 2 is a DTA thermogram of CAC paste

(Secar 71, about 70% Al O ) hydrated at 10°C for 24 hours. It contains

2 3

overlapping C-A-H gel and CAH peaks. The height of the major XRD

10

peak for each hydrate is also indicated by the bar segments at the bottom of

Fig. 2.

Figure 1. An idealized thermal analysis curve for hydrated calcium aluminate cement. [1]