Page 594 - Handbook of Thermal Analysis of Construction Materials

P. 594

Section 4.0 - Asphalt - Bituminous Materials 561

I and II, type III asphalt is thin enough to penetrate masonry, wood, and paper

to provide a bond for other bitumen applications. It is also used to wet

surfaces (e.g., metal). Depending on requirements, type III can be made from

soft, ductile asphalt as well as harder-base asphalts for application to dense,

metal, or porous surfaces. [8]

Emulsion asphalts are easier to handle than other bituminous

products. Water is added in just the necessary amount to decrease viscosity.

Drying involves, primarily, loss of water due to evaporation. Their appli-

cation does not require heat. Furthermore, they have good bonding proper-

ties to either damp or wet surfaces, and are more weather resistant than the

other bitumen types.

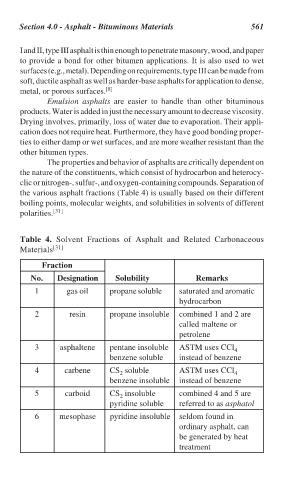

The properties and behavior of asphalts are critically dependent on

the nature of the constituents, which consist of hydrocarbon and heterocy-

clic or nitrogen-, sulfur-, and oxygen-containing compounds. Separation of

the various asphalt fractions (Table 4) is usually based on their different

boiling points, molecular weights, and solubilities in solvents of different

polarities. [31]

Table 4. Solvent Fractions of Asphalt and Related Carbonaceous

Materials [31]

Fraction

No. Designation Solubility Remarks

1 gas oil propane soluble saturated and aromatic

hydrocarbon

2 resin propane insoluble combined 1 and 2 are

called maltene or

petrolene

3 asphaltene pentane insoluble ASTM uses CCl

4

benzene soluble instead of benzene

4 carbene CS soluble ASTM uses CCl 4

2

benzene insoluble instead of benzene

5 carboid CS insoluble combined 4 and 5 are

2

pyridine soluble referred to as asphatol

6 mesophase pyridine insoluble seldom found in

ordinary asphalt, can

be generated by heat

treatment