Page 672 - Handbook of Thermal Analysis of Construction Materials

P. 672

640 Chapter 16 - Paints and Coatings

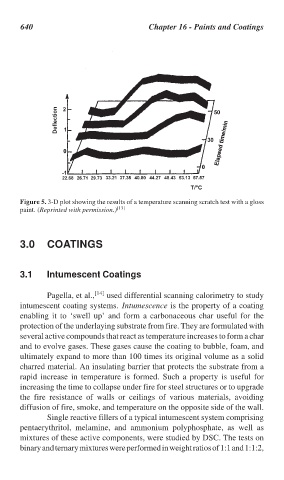

Figure 5. 3-D plot showing the results of a temperature scanning scratch test with a gloss

paint. (Reprinted with permission.) [13]

3.0 COATINGS

3.1 Intumescent Coatings

Pagella, et al., [14] used differential scanning calorimetry to study

intumescent coating systems. Intumescence is the property of a coating

enabling it to ‘swell up’ and form a carbonaceous char useful for the

protection of the underlaying substrate from fire. They are formulated with

several active compounds that react as temperature increases to form a char

and to evolve gases. These gases cause the coating to bubble, foam, and

ultimately expand to more than 100 times its original volume as a solid

charred material. An insulating barrier that protects the substrate from a

rapid increase in temperature is formed. Such a property is useful for

increasing the time to collapse under fire for steel structures or to upgrade

the fire resistance of walls or ceilings of various materials, avoiding

diffusion of fire, smoke, and temperature on the opposite side of the wall.

Single reactive fillers of a typical intumescent system comprising

pentaerythritol, melamine, and ammonium polyphosphate, as well as

mixtures of these active components, were studied by DSC. The tests on

binary and ternary mixtures were performed in weight ratios of 1:1 and 1:1:2,