Page 681 - Handbook of Thermal Analysis of Construction Materials

P. 681

Section 3.0 - Coatings 649

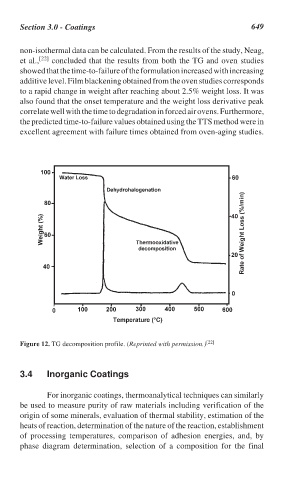

non-isothermal data can be calculated. From the results of the study, Neag,

et al., [22] concluded that the results from both the TG and oven studies

showed that the time-to-failure of the formulation increased with increasing

additive level. Film blackening obtained from the oven studies corresponds

to a rapid change in weight after reaching about 2.5% weight loss. It was

also found that the onset temperature and the weight loss derivative peak

correlate well with the time to degradation in forced air ovens. Furthermore,

the predicted time-to-failure values obtained using the TTS method were in

excellent agreement with failure times obtained from oven-aging studies.

Figure 12. TG decomposition profile. (Reprinted with permission.) [22]

3.4 Inorganic Coatings

For inorganic coatings, thermoanalytical techniques can similarly

be used to measure purity of raw materials including verification of the

origin of some minerals, evaluation of thermal stability, estimation of the

heats of reaction, determination of the nature of the reaction, establishment

of processing temperatures, comparison of adhesion energies, and, by

phase diagram determination, selection of a composition for the final