Page 331 - HVAC Pump Handbook

P. 331

Rishel_CH11.qxd 20/4/06 6:37 PM Page 328

Open Cooling Tower Pumps

328 Pumps for Open HVAC Cooling Systems

The first information that must be obtained in pumping a tower is

to determine the minimum and maximum flow rates required by the

using equipment such as chiller condensers. In the past, there were

simple rules such as 3 gal/min per ton of cooling for an electric chiller.

This assumed that the heat of rejection included the 12,000 Btu/ton

plus 3000 Btu/ton for the chiller compressor and auxiliaries for a total

of 15,000 Btu/ton of cooling. Today, with improved chiller perfor-

mance, the water rates are calculated more carefully. The flow rates

should be checked for the actual chiller or other equipment under con-

sideration at specific design water temperatures such as 95°F return

and 85°F sump water temperatures. If the heat of rejection from the

chiller is expressed in British thermal units per hour at a specific

temperature difference, the following equation can be used to com-

pute the water rate.

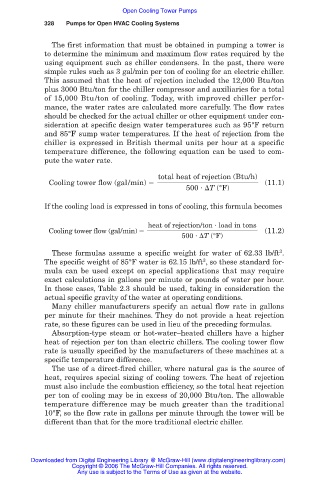

total heat of rejection (Btu/h)

Cooling tower flow (gal/min) (11.1)

500 T (°F)

If the cooling load is expressed in tons of cooling, this formula becomes

heat of rejection/ton load in tons

Cooling tower flow (gal/min) (11.2)

500 T (°F)

3

These formulas assume a specific weight for water of 62.33 lb/ft .

3

The specific weight of 85°F water is 62.15 lb/ft , so these standard for-

mula can be used except on special applications that may require

exact calculations in gallons per minute or pounds of water per hour.

In those cases, Table 2.3 should be used, taking in consideration the

actual specific gravity of the water at operating conditions.

Many chiller manufacturers specify an actual flow rate in gallons

per minute for their machines. They do not provide a heat rejection

rate, so these figures can be used in lieu of the preceding formulas.

Absorption-type steam or hot-water–heated chillers have a higher

heat of rejection per ton than electric chillers. The cooling tower flow

rate is usually specified by the manufacturers of these machines at a

specific temperature difference.

The use of a direct-fired chiller, where natural gas is the source of

heat, requires special sizing of cooling towers. The heat of rejection

must also include the combustion efficiency, so the total heat rejection

per ton of cooling may be in excess of 20,000 Btu/ton. The allowable

temperature difference may be much greater than the traditional

10°F, so the flow rate in gallons per minute through the tower will be

different than that for the more traditional electric chiller.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.