Page 339 - HVAC Pump Handbook

P. 339

Rishel_CH11.qxd 20/4/06 6:37 PM Page 336

Open Cooling Tower Pumps

336 Pumps for Open HVAC Cooling Systems

Maximum Velocity

4 ft./sec.

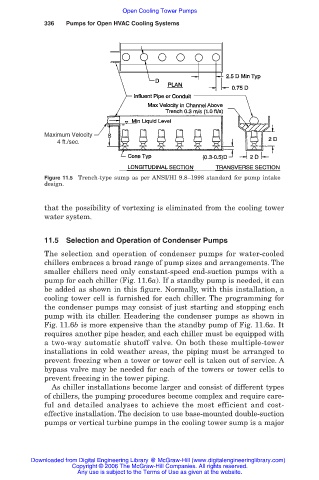

Figure 11.5 Trench-type sump as per ANSI/HI 9.8–1998 standard for pump intake

design.

that the possibility of vortexing is eliminated from the cooling tower

water system.

11.5 Selection and Operation of Condenser Pumps

The selection and operation of condenser pumps for water-cooled

chillers embraces a broad range of pump sizes and arrangements. The

smaller chillers need only constant-speed end-suction pumps with a

pump for each chiller (Fig. 11.6a). If a standby pump is needed, it can

be added as shown in this figure. Normally, with this installation, a

cooling tower cell is furnished for each chiller. The programming for

the condenser pumps may consist of just starting and stopping each

pump with its chiller. Headering the condenser pumps as shown in

Fig. 11.6b is more expensive than the standby pump of Fig. 11.6a. It

requires another pipe header, and each chiller must be equipped with

a two-way automatic shutoff valve. On both these multiple-tower

installations in cold weather areas, the piping must be arranged to

prevent freezing when a tower or tower cell is taken out of service. A

bypass valve may be needed for each of the towers or tower cells to

prevent freezing in the tower piping.

As chiller installations become larger and consist of different types

of chillers, the pumping procedures become complex and require care-

ful and detailed analyses to achieve the most efficient and cost-

effective installation. The decision to use base-mounted double-suction

pumps or vertical turbine pumps in the cooling tower sump is a major

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.