Page 173 - Handbook Of Multiphase Flow Assurance

P. 173

Paraffin wax 169

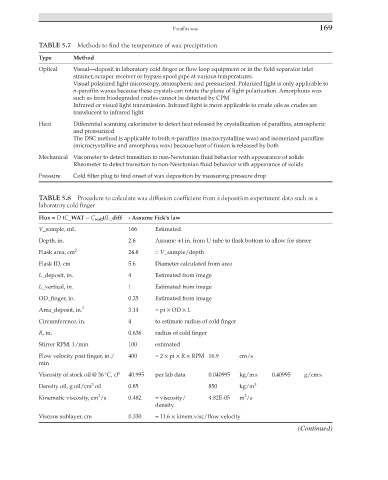

TABLE 5.7 Methods to find the temperature of wax precipitation

Type Method

Optical Visual—deposit in laboratory cold finger or flow loop equipment or in the field separator inlet

strainer, scraper receiver or bypass spool pipe at various temperatures.

Visual polarized light microscopy, atmospheric and pressurized. Polarized light is only applicable to

n-paraffin waxes because these crystals can rotate the plane of light polarization. Amorphous wax

such as from biodegraded crudes cannot be detected by CPM

Infrared or visual light transmission. Infrared light is more applicable to crude oils as crudes are

translucent to infrared light

Heat Differential scanning calorimeter to detect heat released by crystallization of paraffins, atmospheric

and pressurized

The DSC method is applicable to both n-paraffins (macrocrystalline wax) and isomerized paraffins

(microcrystalline and amorphous wax) because heat of fusion is released by both

Mechanical Viscometer to detect transition to non-Newtonian fluid behavior with appearance of solids

Rheometer to detect transition to non-Newtonian fluid behavior with appearance of solids

Pressure Cold filter plug to find onset of wax deposition by measuring pressure drop

TABLE 5.8 Procedure to calculate wax diffusion coefficient from a deposition experiment data such as a

laboratory cold finger

Flux = D (C_WAT − C wall )/L_diff - Assume Fick's law

V_sample, mL 166 Estimated

Depth, in. 2.6 Assume +1 in. from U tube to flask bottom to allow for stirrer

Flask area, cm 2 24.8 = V_sample/depth

Flask ID, cm 5.6 Diameter calculated from area

L_deposit, in. 4 Estimated from image

L_vertical, in. 1 Estimated from image

OD_finger, in. 0.25 Estimated from image

Area_deposit, in. 2 3.14 = pi × OD × L

Circumference, in. 4 to estimate radius of cold finger

R, in. 0.636 radius of cold finger

Stirrer RPM, 1/min 100 estimated

Flow velocity past finger, in./ 400 = 2 × pi × R × RPM 16.9 cm/s

min

Viscosity of stock oil @ 36 °C, cP 40.995 per lab data 0.040995 kg/m s 0.40995 g/cm s

3

Density oil, g oil/cm oil 0.85 850 kg/m 3

2

2

Kinematic viscosity, cm /s 0.482 = viscosity/ 4.82E-05 m /s

density

Viscous sublayer, cm 0.330 = 11.6 × kinem.visc/flow velocity

(Continued)