Page 679 - Handbook of Thermal Analysis of Construction Materials

P. 679

646 Chapter 16 - Paints and Coatings

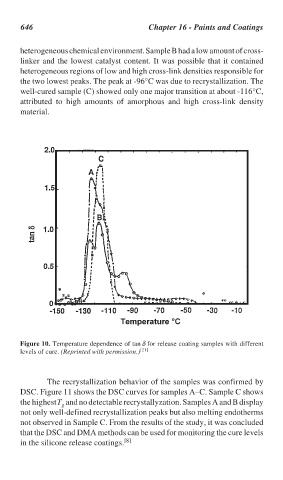

heterogeneous chemical environment. Sample B had a low amount of cross-

linker and the lowest catalyst content. It was possible that it contained

heterogeneous regions of low and high cross-link densities responsible for

the two lowest peaks. The peak at -96°C was due to recrystallization. The

well-cured sample (C) showed only one major transition at about -116°C,

attributed to high amounts of amorphous and high cross-link density

material.

Figure 10. Temperature dependence of tan δ for release coating samples with different

levels of cure. (Reprinted with permission.) [21]

The recrystallization behavior of the samples was confirmed by

DSC. Figure 11 shows the DSC curves for samples A–C. Sample C shows

the highest T and no detectable recrystallyzation. Samples A and B display

g

not only well-defined recrystallization peaks but also melting endotherms

not observed in Sample C. From the results of the study, it was concluded

that the DSC and DMA methods can be used for monitoring the cure levels

in the silicone release coatings. [8]