Page 680 - Handbook of Thermal Analysis of Construction Materials

P. 680

Section 3.0 - Coatings 647

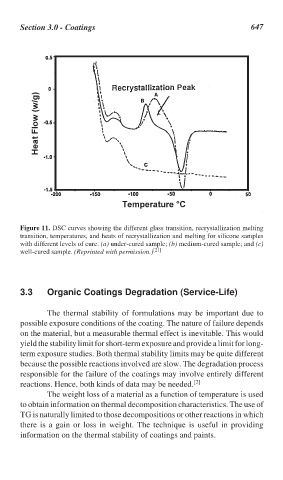

Figure 11. DSC curves showing the different glass transition, recrystallization melting

transition, temperatures, and heats of recrystallization and melting for silicone samples

with different levels of cure. (a) under-cured sample; (b) medium-cured sample; and (c)

well-cured sample. (Reprinted with permission.) [21]

3.3 Organic Coatings Degradation (Service-Life)

The thermal stability of formulations may be important due to

possible exposure conditions of the coating. The nature of failure depends

on the material, but a measurable thermal effect is inevitable. This would

yield the stability limit for short-term exposure and provide a limit for long-

term exposure studies. Both thermal stability limits may be quite different

because the possible reactions involved are slow. The degradation process

responsible for the failure of the coatings may involve entirely different

reactions. Hence, both kinds of data may be needed. [2]

The weight loss of a material as a function of temperature is used

to obtain information on thermal decomposition characteristics. The use of

TG is naturally limited to those decompositions or other reactions in which

there is a gain or loss in weight. The technique is useful in providing

information on the thermal stability of coatings and paints.