Page 199 - Handbook of Adhesives and Sealants

P. 199

Standard Test Methods 169

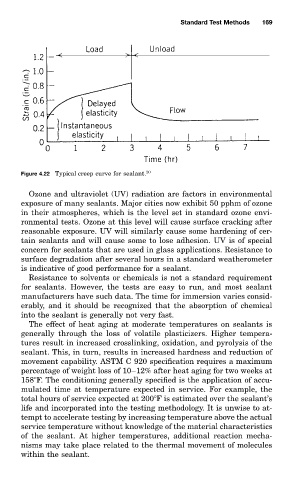

Figure 4.22 Typical creep curve for sealant. 20

Ozone and ultraviolet (UV) radiation are factors in environmental

exposure of many sealants. Major cities now exhibit 50 pphm of ozone

in their atmospheres, which is the level set in standard ozone envi-

ronmental tests. Ozone at this level will cause surface cracking after

reasonable exposure. UV will similarly cause some hardening of cer-

tain sealants and will cause some to lose adhesion. UV is of special

concern for sealants that are used in glass applications. Resistance to

surface degradation after several hours in a standard weatherometer

is indicative of good performance for a sealant.

Resistance to solvents or chemicals is not a standard requirement

for sealants. However, the tests are easy to run, and most sealant

manufacturers have such data. The time for immersion varies consid-

erably, and it should be recognized that the absorption of chemical

into the sealant is generally not very fast.

The effect of heat aging at moderate temperatures on sealants is

generally through the loss of volatile plasticizers. Higher tempera-

tures result in increased crosslinking, oxidation, and pyrolysis of the

sealant. This, in turn, results in increased hardness and reduction of

movement capability. ASTM C 920 specification requires a maximum

percentage of weight loss of 10–12% after heat aging for two weeks at

158 F. The conditioning generally specified is the application of accu-

mulated time at temperature expected in service. For example, the

total hours of service expected at 200 F is estimated over the sealant’s

life and incorporated into the testing methodology. It is unwise to at-

tempt to accelerate testing by increasing temperature above the actual

service temperature without knowledge of the material characteristics

of the sealant. At higher temperatures, additional reaction mecha-

nisms may take place related to the thermal movement of molecules

within the sealant.